- About

- Extreme Bearings

- Bearings Range

- Specailty Bearings

- Applications & Industries

GRW High Precision Miniature & Turbine Bearings

Founded by the brothers Eugene and Hugo Reinfurt in 1942 GRW in Germany have been developing and manufacturing high-precision ball bearings for 60 years.

GRW manufacture ball bearings with rolling bearing tolerances according to DIN 620, accuracy classes P0 to P2, and AFBMA Standard  ABEC1 to ABEC9.

The production of extreme precision miniature bearings is GRW`s core competence.

ABEC1 to ABEC9.

The production of extreme precision miniature bearings is GRW`s core competence.

GRW specialises in the production of high precision, small, miniature and instrument bearings, as well as spindle bearings. In addition, bearing units (pre-assembled units), and special bearings made to customer requirements and high-precision, rotationally symmetrical turned and ground parts are developed and produced

The Standard range covers ball bearings from 1 to 17mm bore and 3 to 40mm diameter, flanged outer rings, extended inner rings and various types of retainers and shields. In addition to this GRW also manufacture bearing units and special ball bearings based on standard parts in order to minimize development times and hence development costs.

Extreme Precision Ball Bearings for Extreme Environments & Conditions

GRW Extreme Precision Bearing Capabilities.

Standard bearings cannot cope with Extreme conditions, GRW are the specialists when it comes to Extreme conditions such as the following.

Heat- Even at blistering temperature up to +450°C GRW`s Extreme Precision Ball Bearings for Extreme Environments & Conditions operate reliably. Equipped with special lubricants and coatings they can even be used in high temperature furnaces, welding systems and turbojets.

Frigid Temperatures- For frigid temperatures down to -270°C special lubricants, coatings as well as as unique bearing materials allow these to operate in these environments. They also exhibit trouble free running in liquid helium.

Chemicals- Destructive forces of acid and alkaline baths are no match for GRW`s special materials. Applications in the chemical industry are as numerous as their unique solutions to solve them.

Salt- Whether surfing or game-fishing, on deep-sea vessels or for offshore applications-GRW`s ball bearing are suited for the challenge. GRW`s Extreme Precsion Ball Bearings for Extreme Environments & Conditions have solutions for fresh and chlorine water applications.

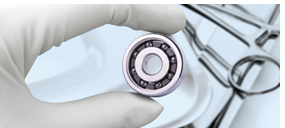

Blood- Blood is an extremely corrosive medium. Even GRW`s smallest and highest precision bearings survive this medium. Whether it be Blood Pumps, Surgical or Dental Handpieces these bearings meet and exceed the highest medical industry requirements.

Sterilisation- During sterilisation of medical and dental instruments ball bearings are subjected to several extreme conditions like cleaning media and heat. With the proper material and our experience we have solve this problem.

Radiation- Whether cosmic radiation or X-ray`s, whether in aeronautics or in the field of medical engineering- by processing special materials and lubricants GRW`s Extreme Precision Ball Bearings for Extreme Environments & Conditions guarantee functionality and reliability for these applications

High Speed- Extreme speeds demand highest precision as well as the tightest tolerances. Applications with speeds up to 500,00 RPM is a standard.

Vibration- High frequent oscillations, vibrations or rocket launch- GRW`s ball bearings also withstand these difficult conditions. Customised bearing solutions guarantee optimised performance and loading capacities.

Vacuum- In aerospace as well as terrestrial applications, the vacuum environment places particularly high demands on bearings. Intelligent solutions with respect to materials and proprietary innovations are elements of GRW`s Extreme Precision Ball Bearings for Extreme Environments & Conditions with cutting edge technology.

GRW Bearing Range

Click Here to View the GRW Catalogue (8.1mb)

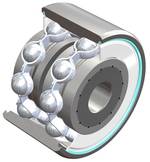

Radial Deep Groove Bearings

Radial Deep Groove Bearings

Single-row deep-groove ball bearings are suitable for use at both low and high speeds. They absorb radial and axial forces.

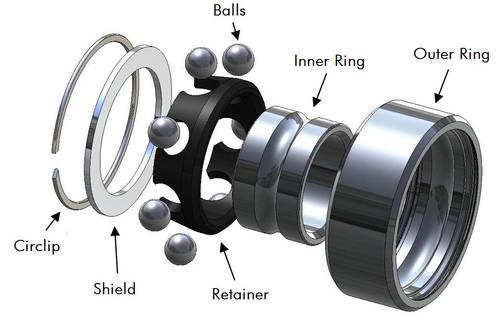

Single row deep-groove ball bearings consist of

- An inner and an outer ring

- A set of balls with cage and (usually) a layer of load-bearing lubricant

- Optional covers or seals.

Application of a suitable lubricant will extend the service life of these ball bearings. GRW offers a range of over 400 different lubricants (oils and greases) from which we can select, based solely on your needs.

Materials and designs In addition to our chromimum steel,for 100Cr6 bearing rings, we also offer the stainless martensitic anti-friction SS (X65Cr13) and SV (X30CrMoN15-1) roller bearing steels. In our hybrid designs the balls are made of ceramic materials. We offer a standard two-part steel ribbon-type cage. Plastic cages in different materials and designs are also available. Non-slip covers are made of corrosion-resistant sheet steel, reinforced Perbunan (nitrile rubber) or fluorine rubber (FKM). Depending upon the design of the bearing, the sealing discs next to the inner ring are made from Teflon-coated glass fiber fabric, reinforced Perbunan (nitrile rubber) or fluorine rubber (FKM). Over 300 different lubricants can be configured based on application requirements.

Standard range and special formats Our standard version deep-groove ball bearings are classified according to ISO or AFBMA. However, when special tolerances and special versions are required in lieu of a standard version, we can accommodate your specifications.

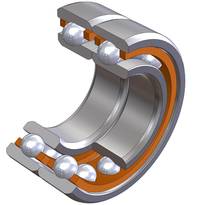

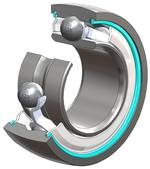

Spindle/Angular Contact Bearings

GRW spindle ball bearings are characterized by the following properties:

GRW spindle ball bearings are characterized by the following properties:

- Manufacture in grade P4 (or ABEC7) or better

- Rings generally made of corrosion-resistant SV30 high-grade steel

- Steel or ceramic balls available for all types

- Machined solid retainer of fiber-reinforced phenolic resin or special materials, for example for applications involving higher temperatures

- 15° (C) or 25° (E) contact angle as a standard

- Optionally, bearings can be paired with three pre-defined preload classes (L, M, S) or individual preload

- Oil or grease lubrication

- Open and closed versions available

- Assembly, lubrication and packaging pursuant to cleanroom grade 10,000

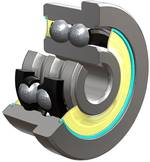

Duplex Bearings in Deep Groove and Angular Contact

Duplex bearings are two matched bearings which provide the following bearing characteristics:

Duplex bearings are two matched bearings which provide the following bearing characteristics:

- accurate bearing positioning in radial and axial directions< from a defined clearance to controlled rigidity.

- limitation of the yield of the system.

- higher load capacity compared to a single bearing.

The matching of the bearings is achieved by loading each single bearing with the desired preload and then relieving the inner and/or outer rings until the surfaces of both rings are flush with each other. Two bearings machined in this way are assembled according to their markings and the instruction on the package, and loaded axially with the specified or required force. Depending on the matching used, either the inner rings or the outer rings, or even both rings are clamped together. The ball bearings must be mounted in accordance with the installation instructions on the packaging labels or the marks on the ball bearings.

GRW Specialty Bearings

GRW not only develops and produces standard and high-precision ball bearings but also all required variants of miniature ball bearings.

|

Superduplex bearings |

|

Extraduplex bearings |

|

Tandem duplex bearings |

|

Bearings with modified external design |

|

Bearings with integrated shaft |

|

Bearings with housing |

Applications & Industries

With over 2,000,000,000 variations, GRW has a solution for your requirements.

Aerospace Technology Bearings

|

|

|

Vacuum Technology Bearings

|

Measurement, Analyis and Flow Control Technology

|

|

|

Medical, Dental & Surgical Bearings

|

Drive and industrial engineering

|

|

|

Model Aircraft, UAV & Hobby

|