About |

Precision Microhydraulics |

|

|

- The Lee Company

- Precision Microhydraulics

- Electro Fluidic Systems

- Industrial Microhydraulics

The Lee Company

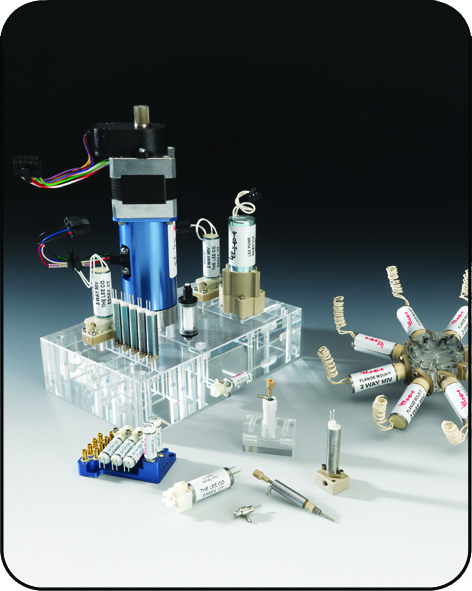

Is the world`s leading manufacturer of miniature precision fluid control products. The Lee products are used in many industries including aerospace, formula 1, oil exploration, land & sea vehicles, medical and scientific instruments.

With over 60 years experience The Lee Company offers a complete line of fluid control products which are known for their superior quality, reliability and performance.

The Lee company specialise in miniaturisation enabling designers to reduce the size and weight of their products, while at the same time or improving quality and manufacturability

The Lee products are divided into three main catagories-use the links above to find out more.

Precision Microhydraulics

|

Lee Expansion Plugs-Leak Tight SealThe Lee Expansion Plugs are the most successful method of of sealing drilled holes with the need for O-Rings, threads or sealants in critical applications.

|

|

Lee Precision Flow RestrictorsSingle and multiple orifice precision flow restrictors for demanding applications such as aerospace, oil tools and race cars. This is the ideal solution for when small size, light weight and reliability is required |

|

Lee Flow Control Valves

|

|

Lee Nozzles-Atomizing and Targeting

|

|

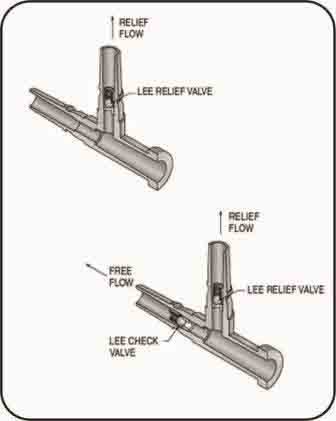

Lee Check ValvesThe Lee Company set the standard with their miniature, pretested cartridge check valves-known around the world for their small size, light weight and proven reliability. Four types of miniature check valves.

|

|

Lee Precision Relief ValvesDesigned to be the smallest valves available for safety relieve applications. The smallest being 3/16" diameter by 1/2" long and weighing only 1.5 grams. Seven different types are produces delivering a wide range of cracking pressure and flow rates. |

|

Lee Shuttle ValvesMiniature 3 port hydraulic valves that allow fluid to flow from one of two onlet sources to a common outlet. Small enough to fit into the head of an actuator offering space and weight saving advantages. Four types available.

|

|

Safety ScreensLee offer a wide variety of safety screens to protect critical fluid control components from rogue contamination. Two types are available.

|

|

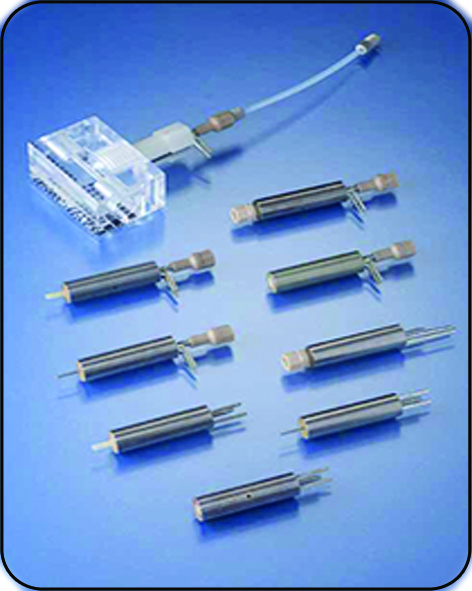

Lee Miniature Piloting Solenoid ValvesThese miniature piloting solenoid valves combine space and with saving advantages with superior performance and reliability.

|

|

Line MountsMany of Lee`s precision components are offered in already installed in flared, flareless or dynamic beam seal unions. Also available is a range of higher pressured restrictors, valves and safety screens built directly into ring locked adaptors. This allows designers to take advantage of the unused space in the adaptors to reduce the size and weight of manifolds.

|

|

Lee Pressure ComponentsLee Company offers two types of pressure snubbing devices and a mechanical peak pressure recorder.

|

Electro-Fluidic Systems

|

Solenoid Valves

|

|

Dispensing Pumps

|

|

Manifold Technology

|

|

Ministac-Miniature Inert System of Tubing & ComponentsThe Lee company`s miniature inert system of tubing and components delivers the ability to precisely control flow rate, pressure, filtration and other performance factors of aggressive fluids. |

|

NozzlesWide range of nozzles for delivering either a precise droplet or atomized fluid.

|

Special Products

Industrial Microhydraulics

|

Check ValvesThese check valves are available for installation into both metal configuration-the internal configuration remains the same but the installation method is different. For Metals

For Plastics

|

|

Pressure Relief ValvesDesigned to protect systems form over pressurisation or to lessen pressure spikes, these pressure relief valves are available for installation into both metal configuration-the internal configuration remains the same but the installation method is different. They are not suited for upstream pressure regulation. For Metals

For Plastics

|

|

Precision Orifices

|

|

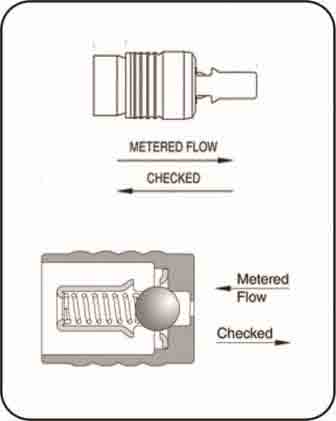

Restrictor Check ValvesModels for both metal and plastic installation-functionally this is an orrifce in series with a check valve

|

|

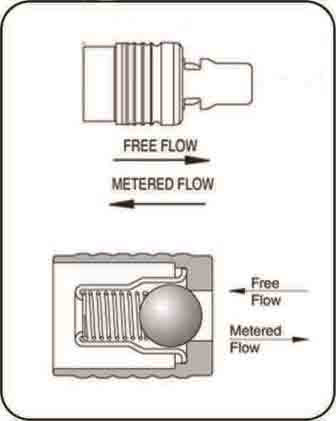

Flow Control ValvesModels for both metal and plastic installation-functionally an orifice in parallel with a check valve in parallel with a check valve in a compact cartidge-style package.

|

|

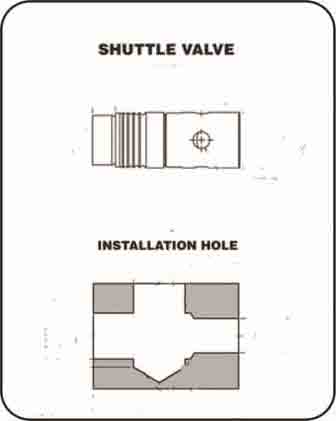

Shuttle ValvesSolves the problem of hydraulic isolation in Manifolds and its compact, non-dented, selective design is ideal as a signal for auxiliary functions.

|

|

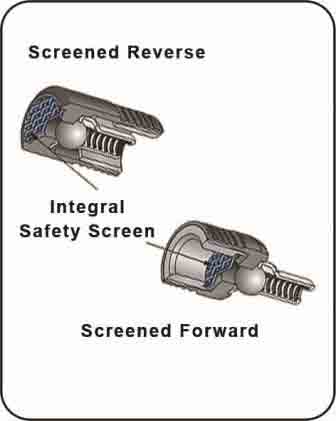

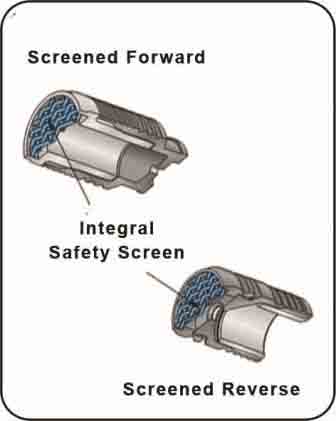

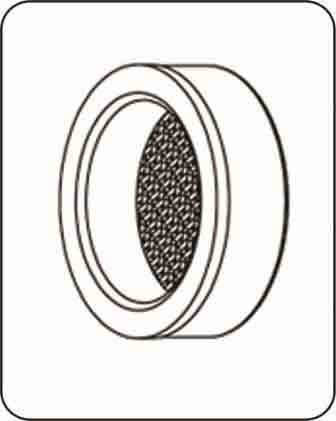

Hydraulic Safety ScreensHydraulic `last chance` safety screens designed to protect critical fluid control components from rogue contamination. Models for both metal and plastic installation

|

|

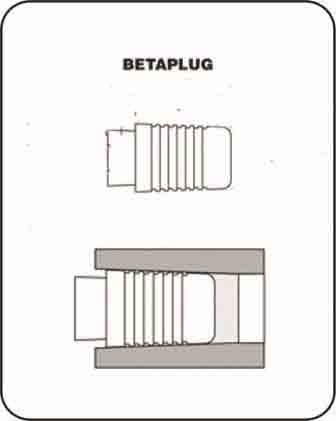

Lee Betaplug Expansion PlugsA pre assembled, on piece, tapered expansion plug engineered to seal fluid passages in meatal castings and plastic housing leak tight without the need for threads or sealants. The Controlled expansion on installation allows the lands and grooves on the plug body to bite into the housing wall crating a leak-tight seal and assuring retention. The tapered design eliminates the need for tight manufacturing tolerances and also allows the for a minimised wall thickness around the plug, even in brittle housing materials. |

|

Lee Products In Plastic FittingsDesigned for both liquid and gas Lee`s highly accurate Orifice pre installed into a male to female leur adaptor with integral safety screen. These are ideal for medical application with the orifice & screen made form 300 series stainless steel and fitting made of medical grade polypropylene. Also available is a series of leur Tee fittings with a relief valve in the branch of the Tee. These are particularly useful for syringe driven systems where a maximum force is required.

|