- About

- Precision Ground Gears

- Precision Gears

- Gear Boxes & Reducers

- Shoulder Screws

Ondrives

With a long established history, Ondrives are a leading manufacturer in precision gear manufacturing and mechanical components. Through continued investment and development the company has built an excellent reputation for Quality, Reliability and Service and has full AS9100 Rev C and ISO 9001:2008 accreditation.

Company Profile

With a long established history, Ondrives are a leading manufacturer of precision gears, gearboxes and mechanical drive components. Through continued investment in state of the art manufacturing equipment and technology we remain at the forefront of precision manufacturing and continue to deliver on quality, reliability and service.

With our qualified and experienced design team we are able to offer a complete service from design, modifications and prototypes through to production volumes. Our engineers are more than happy to assist you with applications, product selection and any technical enquiries, employing the latest calculation and analysis software including KISSsoft.

Quality System

Ondrives' reputation has been built on a commitment to quality, reliability and service. Lloyd's Register Quality Assurance (LRQA) has approved Ondrives Ltd. to both Aerospace standard AS9100 Rev C and BS EN ISO 9001:2008.

Comprehensive inspection ensures compliance to specification including full material traceability, first article inspection reports and inspection reports. These can be supplied on request and all reports are stored digitally against the order.

Capabilities

|

Precision Ground Gears

Ondrives Ground Gears

Ondrives precision ground spur and helical gears with up to 45 degree helix angles are manufactured to quality 3 DIN3962 (AGMA 14+) as standard. Higher accuracies are available from 0.5Mod - 15Mod (50Dp – 1.69Dp) and diameters up to 650mm are also possible.

With special pitches, single and double flank grinding, tip and root relief, optimisation of line contact and in process measurement and inspection Ondrives are able to offer a comprehensive ground gear for all applications.

Incorporating the latest KAPP-Niles ZE400 gear profile grinding machine enables Ondrive to produce both standard and bespoke profiles. As a result Ondrives are able to produce volume batches and prototype quantities without the need for expensive tooling charges.

For more detailed product information including sizing and specifications-please use the links below.

Contact CGB for pricing and availablity

|

|

|

|

|

Precision Gears

Ondrives manufacture a complete range of precision gears available in Steel, Hardened Steel, Stainless Steel, Aluminium Bronze, Cast Iron, Titanium, PEEK® and Delrin. As well as our standard range we also offer bespoke designs to customer drawings. Accredited to AS9100 rev C and ISO 9001:2008 we have the capabilities to supply to all industries including Aerospace, Military, Defence, Medical, Motorsport, Automation and Packaging.

For more detailed product information including sizing and specifications-please use the links below.

Contact CGB for pricing and availablity

|

|

|

|

|

|

|

|

|

|

Gearboxes & Reducers

Ondrives manufacture and offer a complete range of standard and bespoke gearboxes for sale. Worm and wheel, right angle helical, bevel, parallel spur, inline spur, epicyclic servo, taper gear and rack & pinion gearboxes are all available with torque ranges covering 0 – 850Nm.

For more detailed product information including sizing and specifications-please use the links below.

Contact CGB for pricing and availablity

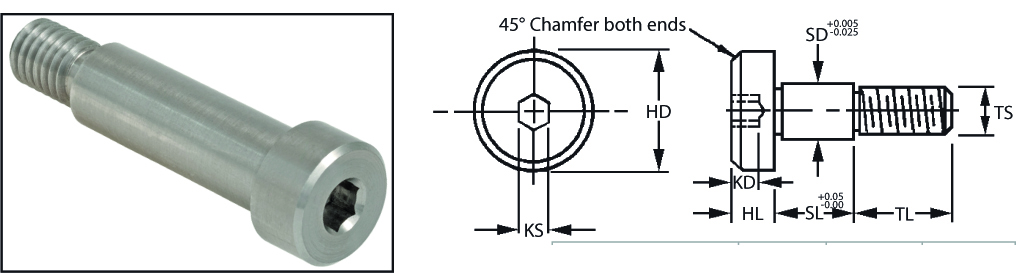

Ondrives Shoulder Screws

Precision Stainless Steel Shoulder Screws-SHS/SHSS/SHSST M3-M10

Material

SHS- Stainless Steel Grade 303 19-9

SHSS-Hard 416 Stainless 26-32 HRC

SHST-Grade 5 Titanium 6AL-4V

| Part Number | ||||||||||

| 303 Stainless | 416 Stainless | Titanium | SD | SL | HD | HL | TL | TS | KS | KD |

| SHS3-4 | SHSS3-4 | SHST3-4 | 3.987 | 4.013 | 6 | 3 | 4 | M3 | 2.0 | 1.6 |

| SHS3-5 | SHSS3-5 | SHST3-5 | 3.987 | 5.013 | 6 | 3 | 4 | M3 | 2.0 | 1.6 |

| SHS3-6 | SHSS3-6 | SHST3-6 | 3.987 | 6.013 | 6 | 3 | 4 | M3 | 2.0 | 1.6 |

| SHS3-8 | SHSS3-8 | SHST3-8 | 3.987 | 8.013 | 6 | 3 | 4 | M3 | 2.0 | 1.6 |

| SHS3-10 | SHSS3-10 | SHST3-10 | 3.987 | 10.013 | 6 | 3 | 4 | M3 | 2.0 | 1.6 |

| SHS4-4 | SHSS4-4 | SHST4-4 | 4.987 | 4.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-5 | SHSS4-5 | SHST4-5 | 4.987 | 5.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-6 | SHSS4-6 | SHST4-6 | 4.987 | 6.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-8 | SHSS4-8 | SHST4-8 | 4.987 | 8.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-10 | SHSS4-10 | SHST4-10 | 4.987 | 10.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-12 | SHSS4-12 | SHST4-12 | 4.987 | 12.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-14 | SHSS4-14 | SHST4-14 | 4.987 | 14.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-16 | SHSS4-16 | SHST4-16 | 4.987 | 16.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-20 | SHSS4-20 | SHST4-20 | 4.987 | 20.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-25 | SHSS4-25 | SHST4-25 | 4.987 | 25.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS4-30 | SHSS4-30 | SHST4-30 | 4.987 | 30.013 | 8 | 4 | 5 | M4 | 2.5 | 2.0 |

| SHS5-4 | SHSS5-4 | SHST5-4 | 5.987 | 4.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-5 | SHSS5-5 | SHST5-5 | 5.987 | 5.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-6 | SHSS5-6 | SHST5-6 | 5.987 | 6.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-8 | SHSS5-8 | SHST5-8 | 5.987 | 8.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-10 | SHSS5-10 | SHST5-10 | 5.987 | 10.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-12 | SHSS5-12 | SHST5-12 | 5.987 | 12.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-14 | SHSS5-14 | SHST5-14 | 5.987 | 14.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-16 | SHSS5-16 | SHST5-16 | 5.987 | 16.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-20 | SHSS5-20 | SHST5-20 | 5.987 | 20.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-25 | SHSS5-25 | SHST5-25 | 5.987 | 25.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS5-30 | SHSS5-30 | SHST5-30 | 5.987 | 30.013 | 10 | 5 | 6 | M5 | 3.0 | 2.4 |

| SHS6-6 | SHSS6-6 | SHST6-6 | 7.987 | 6.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-8 | SHSS6-8 | SHST6-8 | 7.987 | 8.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-10 | SHSS6-10 | SHST6-10 | 7.987 | 10.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-12 | SHSS6-12 | SHST6-12 | 7.987 | 12.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-16 | SHSS6-16 | SHST6-16 | 7.987 | 16.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-20 | SHSS6-20 | SHST6-20 | 7.987 | 20.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-25 | SHSS6-25 | SHST6-25 | 7.987 | 25.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6-30 | SHSS6-30 | SHST6-30 | 7.987 | 30.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6.1-8 | SHSS6.1-8 | SHST6.1-8 | 9.987 | 8.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6.1-10 | SHSS6.1-10 | SHST6.1-10 | 9.987 | 10.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6.1-12 | SHSS6.1-12 | SHST6.1-12 | 9.987 | 12.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS6.1-16 | SHSS6.1-16 | SHST6.1-16 | 9.987 | 16.013 | 12 | 6 | 11 | M6 | 4.0 | 3.2 |

| SHS8-8 | SHSS8-8 | SHST8-8 | 9.987 | 8.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS8-10 | SHSS8-10 | SHST8-10 | 9.987 | 10.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS8-12 | SHSS8-12 | SHST8-12 | 9.987 | 12.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS8-16 | SHSS8-16 | SHST8-16 | 9.987 | 16.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS8-20 | SHSS8-20 | SHST8-20 | 9.987 | 20.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS8-25 | SHSS8-25 | SHST8-25 | 9.987 | 25.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS8-30 | SHSS8-30 | SHST8-30 | 9.987 | 30.013 | 14 | 7 | 12 | M8 | 5.0 | 4.0 |

| SHS10-12 | SHSS10-12 | SHST10-12 | 11.987 | 12.013 | 20 | 8 | 16 | M10 | 6.0 | 4.8 |

| SHS10-16 | SHSS10-16 | SHST10-16 | 11.987 | 16.013 | 20 | 8 | 16 | M10 | 6.0 | 4.8 |

| SHS10-20 | SHSS10-20 | SHST10-20 | 11.987 | 20.013 | 20 | 8 | 16 | M10 | 6.0 | 4.8 |

| SHS10-25 | SHSS10-25 | SHST10-25 | 11.987 | 25.013 | 20 | 8 | 16 | M10 | 6.0 | 4.8 |

| SHS10-30 | SHSS10-30 | SHST10-30 | 11.987 | 30.013 | 20 | 8 | 16 | M10 | 6.0 | 4.8 |

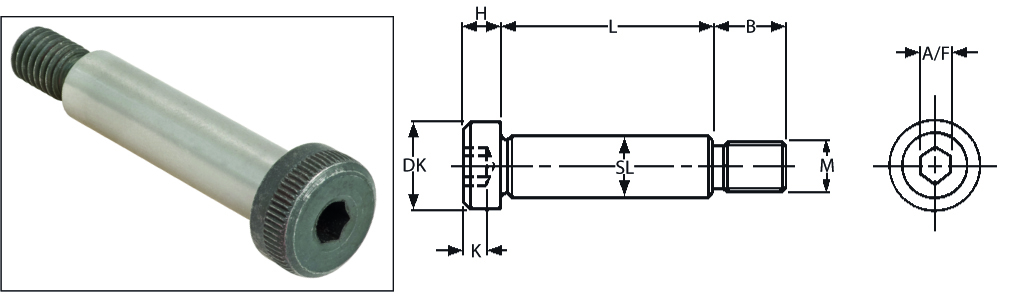

Hardened Steel Shoulder Screws-HSS M5-M8

Material

Alloy Steel-High Grade 12.9 Quality BS4168 Pt.7 (ISO 7379)

| Part | Thread | ||||||||

| Number | M | L +0.25 | Pitch | B | DK | K | SL* | H | AF |

| HSS5-10 | M5 | 10 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS5-12 | M5 | 12 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS5-16 | M5 | 16 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS5-20 | M5 | 20 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS5-25 | M5 | 25 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS5-30 | M5 | 30 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS5-40 | M5 | 40 | 0.80 | 9.75 | 10.22 | 2.4 | Ø6 | 4.5 | 3 |

| HSS6-12 | M6 | 12 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS6-16 | M6 | 16 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS6-20 | M6 | 20 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS6-25 | M6 | 25 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS6-30 | M6 | 30 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS6-40 | M6 | 40 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS6-50 | M6 | 50 | 1.00 | 11.25 | 13.27 | 3.3 | Ø8 | 5.5 | 4 |

| HSS8-16 | M8 | 16 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-20 | M8 | 20 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-25 | M8 | 25 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-30 | M8 | 30 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-40 | M8 | 40 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-50 | M8 | 50 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-60 | M8 | 60 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-70 | M8 | 70 | 1.25 | 13.25 | 16.27 | 4.2 | Ø10 | 7.0 | 5 |

| HSS8-80 | M8 | 80 | 1.25 | 13.25 | 16.27 | 4.9 | Ø10 | 7.0 | 5 |

| HSS10-16 | M10 | 16 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-20 | M10 | 20 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-25 | M10 | 25 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-30 | M10 | 30 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-40 | M10 | 40 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-50 | M10 | 50 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-60 | M10 | 60 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-70 | M10 | 70 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-80 | M10 | 80 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-90 | M10 | 90 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS10-100 | M10 | 100 | 1.50 | 16.40 | 18.27 | 4.9 | Ø12 | 8.0 | 6 |

| HSS12-30 | M12 | 30 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-40 | M12 | 40 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-50 | M12 | 50 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-60 | M12 | 60 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-70 | M12 | 70 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-80 | M12 | 80 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-90 | M12 | 90 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| HSS12-120 | M12 | 120 | 1.75 | 18.40 | 24.33 | 6.6 | Ø16 | 10.0 | 8 |

| * Tolerances vary | |||||||||

| Nominal | Thread Section Tensile Strength |

Shoulder Tensile Strength |

Thread Neck Tensile Strength |

Tightening Torque | |||||

| Size | M | Kg | KN | Kg | KN | Kg | KN | Kgfm | Nm |

| 6 | M5 | 1,732 | 16.99 | 2,087 | 20.47 | 777 | 7.62 | 0.78 | 7.61 |

| 8 | M6 | 2,450 | 24.03 | 3,710 | 36.38 | 1,112 | 10.9 | 1.34 | 13.14 |

| 10 | M8 | 4,465 | 43.77 | 5,798 | 56.86 | 2,122 | 20.81 | 3.43 | 33.63 |

| 12 | M10 | 7,075 | 69.38 | 8,349 | 81.88 | 3,446 | 33.79 | 6.17 | 60.56 |

| 16 | M12 | 10,250 | 100.52 | 14,842 | 145.55 | 5,079 | 49.8 | 12.3 | 120.62 |

| 20 | M16 | 19,150 | 187.8 | 23,191 | 227.43 | 9,828 | 96.38 | 27.92 | 273.8 |

| 24 | M20 | 29,850 | 292.73 | 33,395 | 327.49 | 15,518 | 152.18 | 50.14 | 491.7 |

ContactCGB for more information

Ground Spur Gears

Ground Spur Gears

Ground Helical Gears

Ground Helical Gears

Ground Gear Racks

Ground Gear Racks

Ground Rack Pinions

Ground Rack Pinions Ground Worms

Ground Worms

Precision Spur Gears

Precision Spur Gears Precision Anti-Backlash Spur Gears

Precision Anti-Backlash Spur Gears Precision Pinion Shafts

Precision Pinion Shafts Precision Gear Racks

Precision Gear Racks

Precision Parallel Helical Gears

Precision Parallel Helical Gears Precision Crossed Helical Gears

Precision Crossed Helical Gears Precison Worms

Precison Worms

Precision Wormwheels

Precision Wormwheels Precision Anti-Backlash Wormsheels

Precision Anti-Backlash Wormsheels Precision Bevel Gears

Precision Bevel Gears