CeramicSpeed

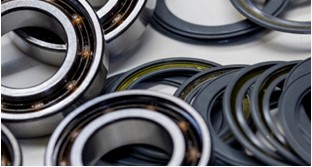

Ceramic Speed manufactures a complete range of Ceramic Hybrid ball bearings and roller bearings which feature a higher performance than traditional steel bearings. These bearings assist industries and applications to achieve new competitive advantages.

Advantage of CeramicSpeed Bearings

- 4-8 times longer lifetime

- Investment is usually repaid in the first lifecycle of a traditional bearing

- Lower operating temperature - 10-20 °C lower than steel bearings

- Lower energy consumption

- Higher RPM - typically 50 % higher than steel bearings

- Run better with suboptimal lubrication

- Extremely resistant to foreign particles

Products

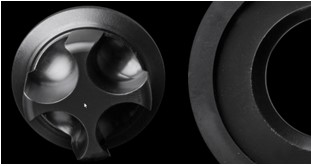

CeramicSpeed Balls

The balls CeramicSpeed use are fundamental to the properties of CeramicSpeed bearings. The extremely high quality balls used are manufactured from Silicon Nitride (Si3Ni4).

Ceramic Speed balls are produced by a few, select manufacturers capable of supplying balls of certified high quality.

The increased hardness of the ball means that the contact area between the ball and the track is reduced, which leads to lower friction, higher potential speeds and less energy wasted. The hardness and extremely smooth surface also means that the balls are far more durable than steel balls.

Insulate Bearings

CeramicSpeed Insulate ball bearings are custom made for electrical motors and your guarantee against damage caused by stray currents.

The ceramic balls used for this product series are non-conductive and have an insulating ability of 15 kV per mm - higher than that of atmospheric air.

CeramicSpeed Insulate bearings are suitable for a wide range of industrial motors and could be configured to exact customer needs.

Corrotec Bearings

The food industry places high demands on bearings. Besides high performance and extended lifetime, bearings require approval and certification for use in the food industry.

CeramicSpeed Corrotec bearings are approved and suitable for use in the food industry. The Corrotec series features bearings made of stainless steel with ceramic balls and lubricant approved for use in the food industry

- Food industry (FDA) approved lubricant

- 4-8 times longer lifetime than conventional bearings

- Lubricant type and fill level customised according to the bearing’s application

- High load bearing capacity

- Lower inertia reduces the load on the races

- Case Studies

Xtreme Bearings

Xtreme Ceramic Bearing balls are harder and tougher than anything that comes into contact with them: dust, grit, metal filings, tiny mineral fragments… Imagine a bearing in which all contaminants are ground to microscopic powder by the balls themselves - a bearing that is unlikely to fail or fracture.

That's the Xtreme bearing series from CeramicSpeed

High Temp Bearings

The CeramicSpeed HighTemp (High Temperature) ball bearing series is designed for use in operating environments where the temperature reaches up to 260 °C or even as high as 350 °C. Ceramic balls have a low coefficient of thermal expansion – only a quarter of that of steel balls - and don’t microweld to the races. These properties mean that CeramicSpeed HighTemp bearings can be used with a lower degree of play than other high temperature bearings, improving their function at high RPM. Ceramic balls also create a lower degree of wear on the races. When used in combination with high-quality lubricants, these bearings provide you with a solution which has an extremely long lifetime in high temperature operating environments.

Custom Bearings

Can't find the bearing that suits your needs? CeramicSpeed can make it for you.

Their CustomBuild series is based around the idea of listening and creating the bearing solutions you need. At CeramicSpeed they employ specialists with many years of experience in the development of specialised bearings for any application that does not fit the standard product categories.Technologies

Coatings

CeramicSpeed supply coatings for all types of steel - including stainless steel.

Advantages of CeramicSpeed Coating Systems

- Increases the lifetime of replaceable parts by 2-4 times

- Reduced wear

- Lower friction

- Reduced replacement frequency of parts reduces service costs

- Reduced risk of breakdown

- Fast return on investment

- Increased corrosion resistance

- Reduced need for lubrication

CorroCoat - Total coating / entire surface

- Bearing rings in ball bearings

- Other wear parts which need to be corrosion resistant

HardCoat - Coating of contact surfaces

- Rolling elements in roller bearings

- Races in ball and roller bearings

- Wear parts where increased wear resistance and reduced friction are necessary

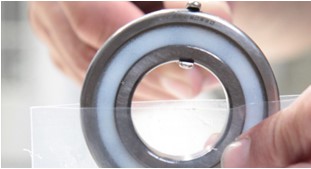

Seals

CeramicSpeed offers three seal options for their deep groove ball bearings:

Seals type RZ(2RZ)

A non-friction rubber seal which grants optimal protection for the bearing without creating undue friction even at higher engine speeds.

Seals type RS (2RS)

Friction seal offering optimal protection for the bearing while limiting potential rotation and creating friction.

Seals type Z (2Z)

Steel zhields providing fundamental bearing protection without creating friction and without limiting the bearing's potential rotation speed.

Grease chamber seals (GCS)

Avialble for Y/UC bearings 20-80mm the GCS sealing system is attached on top of the existing seal creating a barrier against contamination.

Black Plate Specifications (BPS)

This consistes of BPS plate with seals and lubrication nipple. Mounted betweed the bearing and equipment it forms a 3-4mm grease filled chamber for protection.

Lubricant

CeramicSpeed offer a range of commercially available quality lubricants to suite the application and environoment.Lubricants are critical for optimal ball and roller bearing function. The correct lubrication is essential for the service life of the bearing as well as for the temperatures and noise levels. Properly lubricated, CeramicSpeed bearings have even longer service lives, are more reliable and even better protected against contamination and corrosion.

SLT

CeramicSpeed SLT (Solid Lubrication Technology) is a polymer matrix saturated with lubrication oil. The matrix ensures that the oil is kept on the functional surfaces of the bearing under very harsh conditions while at the same time preventing moisture and foreign particles from entering the bearing. CeramicSpeed SLT is food-grade approved and can be combined with most sealed bearing types. In combination with their stainless rings and high-grade ceramic balls, it is an extremely durable and maintenance-free solution for demanding applications.

Steel Alloys

Xtreme and Insulate bearings rings are made from 100Cr6 (Nr. 1.3505). 100Cr6 presents an optimum compromise between surface hardness and core toughness and it’s machinability allows for raceways with super smooth surfaces allowing quiet and long lasting bearings.

Corrotec and High Temp bearing series are made from AISI 440C or AISI420 stainless steels. Both materials are superior to 100Cr6 in chemical resistance and hence offers a fine compromise between wear resistance and pure survival in wet or chemically contaminated environments as well as safe running with food contact approval.

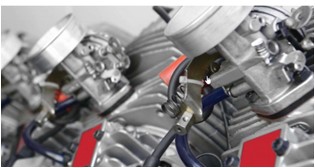

Motorsport

CeramicSpeed Bearings makes a remarkable difference in the engine, wheel hubs, transmission or suspension in 2 and 4 wheeled motor sport vehicles & eco racing platforms such as solar powered vehicles.

Engine

Engine-with the lower weight, increase stiffness and reduced friction of CeramicSpeed Bearings can deliver faster accellerations, more power and improved drivability.

Wheel Hub

Wheel Hub - CeramicSpeed Bearings properties of lower friction, increased stiffness and impact resistance are and advantage in wheel hub applications

Suspension

Suspension - CeramicSpeed Bearings lower friction and high impact resistance made them ideal for movement and forces seen in dynamic suspension applications.

Transmission

Transmission-CeramicSpeed Bearings are highly resistant to contamination that is produced by the mechanical wear of sorrounding components in transmissions.