- About

- Permanent

- Electric Hysteresis

- Eddy Current

- Bottle Capping

- Magtork

- Couplings

- Fastlock

Quality, Innovation, Attention To Detail

Since 1984 Magnetic Technologies have been designing and manufacturing high quality permanent magnet brakes, clutches and couplings. These include: permanent magnet synchronous shaft couplings, permanent magnet hysteresis and eddy current devices, and the accessories required for mounting our product in your system.

Some industries that they serve include: capping, wire & cable, fiber-optic, aerospace, converting, mechanical power transmission, medical, chemical pumps, mixers, and oil well applications.

Whether you choose one of their standard models or require a custom design, their engineers understand tension and torque transmission. They know from experience the various applications that work best for magnetic brakes, couplings and clutches.

Their products are modular in design. This makes them more versatile and reduces your inventory of duplicate parts and assemblies. The shafts on many of Their units can be modified or reversed easily for easy insertion into your assemblies. Their clutches have larger bores and clamp collars to simplify alignment and mounting. Their standard brakes use ball bearings while their heavy-duty units incorporate roller bearings to meet overhung load requirements.

Magnetic Brakes and Clutches IS THEIR PASSION

For tensioning and torque limiting applications, their permanent magnetic brakes and clutches are the obvious choice. Permanent magnetic brakes and clutches are smooth by nature because they use no friction elements to wear or change with time. Permanent magnetic brakes and clutches use no electricity so they are explosion proof and can be used in applications where it is difficult or impossible to get electricity. Because of the Hysteresis design, the torque generated is constant and does not vary with speed. Their permanent magnetic brakes and clutches are designed to run continuously. At Magnetic Technologies, they have been building permanent magnetic hysteresis type brakes and clutches since 1984. This is all they do.

Permanent Magnetic Hysteresis Brakes & Clutches

Advantages

Frictionless design principle with virtually no wear. This provides such advantages as:

Frictionless design principle with virtually no wear. This provides such advantages as:

- longer expected life,

- superior torque repeatability,

- life-cycle cost advantages,

- broad speed range,

- excellent environmental stability and

- superior operational smoothness.

How They Operate

All important internal clearances are ground to tolerances of less than .025mm (.001 in). Magnet Assemblies (purple) surround our hysteresis disc (gold). When like poles face each other, they produce maximum magnetic saturation, forcing lines of flux to travel circumferential through the hysteresis disc. This produces Maximum torque.

When opposite poles face each other, they produce minimum saturation of the hysteresis disc. The lines of flux travel right through the hysteresis disc. Combinations of adjustment angles between these two extremes gives infinite adjust ability. Because there are no contacting surfaces, the setting can be maintained indefinitely.

Size Range and Selection Criteria

Quality permanent magnetic tensioning devices for pay-off and torque limiting. Currently on offer 17 product lines ranging from 0.04 in/oz. to 140 in/labs.

Quality permanent magnetic tensioning devices for pay-off and torque limiting. Currently on offer 17 product lines ranging from 0.04 in/oz. to 140 in/labs.

To see the range of models available view on the Magnetic Technologies Page.

To select the correct size for you application contact CGB or use the following link to go through the selection criteria on the Magnetic Technologies website- Selection Criteria

Electric Hysteresis Brakes

Video: Closed Loop FeedbackFeatures -Magnetic Technoligies Electric Hysteresi Brake -FMS Load Cell -FMS BKS309 Amplifier/Controller |

Advantages

Advantages

The superior design of these hysteresis devices provides several inherent advantages over magnetic-particle and friction devices. They operate on a frictionless design principle with virtually no wear. This provides such advantages as: longer expected life, superior torque repeatability, life-cycle cost advantages, broad speed range, excellent environmental stability and superior operational smoothness.

Operating principles

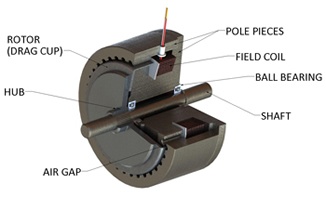

The hysteresis effect in magnetism is applied to torque control by the use of two basic components - a reticulated pole structure and a special steel rotor/shaft assembly - fitted together but not in physical contact. Until the pole structure is energized, the drag cup can spin freely on its shaft bearings. When a magnetizing force from a field coil is applied to the pole structure, the air gap becomes a flux field and the rotor is magnetically restrained, providing a braking or clutching action between the pole structure and rotor.

Control

Control

In a Current Controlled Electric Hysteresis Brake, adjustment and control of torque is provided by a field coil. This allows for complete control of torque by adjusting DC current to the field coil. Adjustability from a minimum value (bearing drag) to a maximum value of 15 - 35% above rated torque is possible. In a Permanent Magnet Hysteresis Brake, the field coil is replaced by magnets which provide the precise field strength necessary to produce rated torque without the need of electrical excitation. Physical realignment of the pole structure will result in changes in torque.

Longer expected life

Hysteresis Brakes produce torque strictly through a magnetic air gap, making them distinctly different from mechanical-friction and magnetic particle devices. Because hysteresis devices do not depend on friction or shear forces to produce torque, they do not suffer the problems of wear, particle aging, and seal leakage. As a result, hysteresis devices typically have life expectancies many times that of friction and magnetic particle devices.

Superior torque repeatability

Superior torque repeatability

Because torque is generated magnetically without any contacting parts or particles, Hysteresis Brakes provide superior torque repeatability. Friction and magnetic particle devices are usually subject to wear and aging with resultant loss of repeatability. Hysteresis devices will repeat their performance precisely, to ensure the highest level of process control.

Broad speed range

Broad speed range

Hysteresis devices offer the highest slip speed range of all electric torque control devices. Depending on size, kinetic power requirements and bearing loads, many Hysteresis Brakes can be operated at speeds in excess of 10.000 rpm. In addition, full torque is available even at zero slip speed and torque remains absolutely smooth at any slip speed.

Operational smoothness

Operational smoothness

Because they do not depend on mechanical friction or particles in shear, Hysteresis Brakes are absolutely smooth at any slip ratio. This feature is often critical in wire drawing, packaging, and many other converting applications.

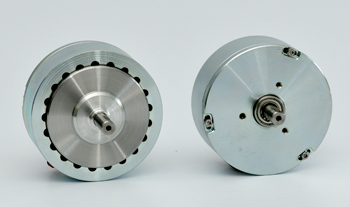

Eddy Current Clutches

Features & Benefits

Features & Benefits

Accurate tension in ounces or grams

Large bores and narrow widths

No electricity, no slip rings

No break-away torque

No wearing parts

How Eddy Current Clutches Work

Eddy Current clutches give torque as a function of RPM. The faster you turn the rotor, the more torque. This means by increasing or decreasing the RPM, you can get infinite torque adjustment. Typically, we rate the clutch with a gain factor (k), which is gram millimeters/rpm or Newton meters/rpm and we design the clutch to have an operating “slip rpm” between 1 and 300 rpm. Time Proven Designs At Magnetic Technologies Ltd. we have been building custom eddy current clutches since 1984. We are constantly fine tuning and improving our designs. Today, we have hundreds of custom designed units in use. We have eddy current clutches running on every continent. Because of our maintenance and retro-fit programs, we have a chance to see how our clutches perform over time. Most are still in use even after 15+ years of continual service!

Typical Applications:

Generally, eddy current clutches are used for take-up applications on slitting and rewinding machinery. Eddy Current Clutches give very accurate tension control.

Bottle Capping Clutches

The smooth "ratchet free" alternative for bottle capping

The smooth "ratchet free" alternative for bottle capping

Most bottle capping clutches today are magnetic, but of the synchronous design. The synchronous design uses two sets of opposed magnets to achieve the desired torque. The result is a noisy, ratcheting effect.

These clutches tighten the cap much like an impact wrench tightens the lugs on an automobile tire. With today's thinner materials, higher speeds and need for more precise torque, synchronous clutches are quickly becoming obsolete in the workplace.

The Hysteresis Design is Built Better and Lasts Longer

In the hysteresis design, the magnets drive the torque through a special material called the hysteresis disc. The hysteresis disc generates a completely smooth, highly repeatable torque to the bottle cap. The result is better torque to the cap and longer life for the clutch. Using the highest quality magnets, design techniques delivers the best clutch for your money.

Magnetic Technologies can custom build OEM designs and offer standard stainless steel bottle capping clutches to replace most competitive brands. They offer rebuild and clutch exchange programs.

Magnetic Technologies Ltd have been designing and building hysteresis clutches since 1984.

For Pharmaceuticals (952 Type Clutch)

|

|

For Beverage/Water (MCC 30 Type Clutch)

|

|

For Chemicals/Large Caps (MCC 50 Type Clutch)

|

|

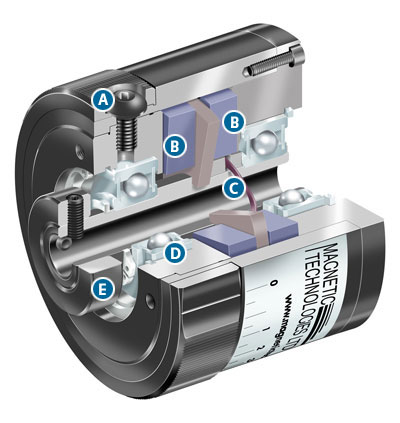

Magtork™ Brakes and Clutches

Magtork™ Hysteresis Brakes and Clutches are a direct replacement for Magpower Perma-Tork® and Warner Precision Tork® magnetic clutches. Magtork™ magnetic brakes and clutches fit competitive bolt circles and have the same outside dimensions for easy retro-fitting. Magtork™ brakes and clutches come standard with upgrade features shown on the cut-away image below. Magtork™ offers a wider variety of available bore sizes than the competition for better compatibility in your application.

Why Are MTL Brakes and Clutches Better?

Clamping Screw Large, industrial knurled adjustment with socket cap screw for locking the adjustment. Most importantly, the adjustment has positive stops at "0" and "100%".

Matched Magnetic Assemblies Because we do all our own magnetizing in house, we are better able to control flux density in the magnetic assemblies assuring better adjustability and consistency unit to unit.

Wave Spring To eliminate any tolerance build up, we add a special wave spring to take out any accumulated tolerance and to pre-load the bearings with just the right amount of pressure to allow easy adjustment and virtually zero end play in the rotor.

Ball Bearing Because the bearing is the only wearing part, we go to special lengths to buy the best sealed ball bearings available. We use a special high temperature lubricant to add years of long life.

Set Screw Collar Most manufacturers simply tap the rotor to allow shaft connection. We've learned small rotors need an extra set screw collar, so we've added one, which makes mounting easier for you. More importantly we can now use an oversized set screw to give plenty of thread engagement and guarantee a positive shaft connection.

Competitive Cross Reference Chart

| Magnetic

Tech Magtork™ Part# |

Approximate

Torque (lb. in.) |

MagPowr Perma-Tork® Part # |

Warner Precision Tork® Part # |

| MTL0.06-5 | 0.01-0.06 | Not Available | Not Available |

| MTL0.06-3/16 | 0.01-0.06 | HC01-1 | MB1-3/16 |

| MTL0.5 | 0.03-0.44 | HC05-1 | Not Available |

| MTL0.13-5 | 0.01-0.13 | Not Available | Not Available |

| MTL0.13-3/16 | 0.01-0.13 | Not Available | Not Available |

| MTL1.25-1/4 | 0.06-1.25 | HC2-14 | MC2-14 |

| MTL1.25-6 | 0.06-1.25 | Not Available | Not Available |

| MTL5-3/8 | 0.20-5.00 | Not Available | MC3-38 |

| MTL5-8 | 0.20-5.00 | Not Available | Not Available |

| MTL10-3/8 | 0.50-10.6 | HC4-38 | MC4-38 |

| MTL10-1/2 | 0.50-10.6 | HC4-12 | MC4-12 |

| MTL10-5/8 | 0.50-10.6 | HC4-58 | MC4-58 |

| MTL10-16 | 0.50-10.6 | Not Available | Not Available |

| MTL25-3/8 | 1.00-25.0 | HC5-38 | MC5-38 |

| MTL25-1/2 | 1.00-25.0 | HC5-12 | MC5-12 |

| MTL25-5/8 | 1.00-25.0 | HC5-58 | MC5-58 |

| MTL25-3/4 | 1.00-25.0 | Not Available | MC5-34 |

| MTL25-7/8 | 1.00-25.0 | Not Available | MC5-78 |

| MTL25-1 | 1.00-25.0 | Not Available | MC5-1 |

| MTL25-16 | 1.00-25.0 | Not Available | Not Available |

| MTL50-3/8 | 2.00-50.0 | Not Available | MC5.5-38 |

| MTL50-1/2 | 2.00-50.0 | Not Available | MC5.5-12 |

| MTL50-3/4 | 2.00-50.0 | Not Available | MC5.5-34 |

| MTL50-7/8 | 2.00-50.0 | Not Available | MC5.5-78 |

| MTL50-1 | 2.00-50.0 | Not Available | MC5.5-1 |

| MTL70-5/8 | 3.00-70.0 | HC6-58 | MC6-58 |

| MTL70-3/4 | 3.00-70.0 | HC6-34 | MC6-34 |

| MTL70-7/8 | 3.00-70.0 | Not Available | MC6-78 |

| MTL70-16 | 3.00-70.0 | Not Available | Not Available |

| MTL140 | 6.00-140 | Not Available | MC6D |

Magnetic Couplings

Simple Concept: Opposite Poles Attract.

This attraction is how we transmit torque from one magnetic hub to another. By driving one magnetic hub, torque is transmitted magnetically to the other magnetic hub. This can be done through the air or through a non-magnetic containment barrier such as stainless steel or fibre glass, allowing complete isolation of the inner magnetic hub from the outer magnetic hub.

There are no contacting parts!

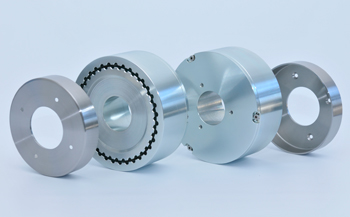

Disc Couplings

Disc type couplings consist of two couplings consist of two opposing discs with powerful rare earth magnets. Due to its simple flat design, you can have angular misalignment of 3° or parallel misalignment of up to 1/4 inch and still transmit nearly full rotational torque.

Benefits and features-

Benefits and features-

-

No wearing parts

-

Synchronous design, no slip at any speeds.

-

No physical contact between driving and driven parts.

-

Simplifies containment barrier.

-

Custom designs available.

Visit Magnetic Technologies for size selection

Co-Axial Couplings

The outer hub consists of a series of rare earth magnets that are attached to the inside diameter of the steel hub. The inner hub consists of a series of rare earth magnets that are attached to the outside diameter of a steel rotor. The inner hub is then completely sealed in stainless steel to protect the magnets and rotor from damage and corrosive substances.

Benefits and features-

Benefits and features-

-

Eliminates rotating seals.

-

No wearing parts.

-

Synchronous design, no slip at any speeds.

-

Custom designs available

Visit Magnetic Technologies for size selection

Pump Type

Magnetic Technologies make several magnetic pump drive kits. Contact CGB for more information.

Standard features

Standard features

-

Heavy duty steel bellhousing with large access hole and weep hole.

-

Increased inner clearance for viscous fluids.

-

Capture key on motor hub.

-

Fits most IEC and NEMA motor mounts

-

Flow-through inner hub.

-

Jack screws on bellhousing for easy removal.

FastLock

Used to retain spools on shafts. They allow for quick and easy loading and unloading of spools. Available in Metric and Imperial sizes

-

A "Fast on" "Fast off" Shaft Collar

One hand operation, no tools required

Usable on non-hardened shafts

Metric |

Dimensions |

Imperial |

Dimensions |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

Model |

A |

B |

C |

kg |

Model |

A |

B |

C |

lb |

|

| FL-6mm | 6 | 18.5 | 26 | 0.03 | FL-.250 | .250 | 0.73 | 1.00 | 0.07 | |

| FL-8mm | 6 | 18.5 | 26 | 0.03 | FL-.312 | .3125 | 0.73 | 1.00 | 0.07 | |

| Fl-10mm | 10 | 22 | 45 | 0.08 | FL-.375 | .375 | 0.85 | 1.78 | 0.19 | |

| FL-15mm | 15 | 28 | 45 | 0.13 | FL-.437 | .437 | 0.85 | 1.78 | 0.18 | |

| FL-16mm | 16 | 28 | 45 | 0.13 | FL-.500 | .500 | 1.10 | 1.78 | 0.29 | |

| Fl-18mm | 18 | 31 | 45 | 0.14 | FL-.562 | .562 | 1.10 | 1.78 | 0.26 | |

| Fl-20mm | 20 | 37 | 45 | 0.21 | FL-.625 | .625 | 1.10 | 1.78 | 0.25 | |

| Fl-22mm | 22 | 37 | 45 | 0.22 | FL-.750 | .750 | 1.23 | 1.78 | 0.31 | |

| FL-25mm | 25 | 37 | 45 | 0.19 | FL-.875 | .875 | 1.45 | 1.78 | 0.37 | |

| FL-30mm | 30 | 50 | 45 | 0.39 | FL-1.00 | 1.000 | 1.45 | 1.78 | 0.32 | |

| FL-32mm | 32 | 57 | 48 | 0.53 | FL-1.25 | 1.250 | 2.23 | 1.87 | 1.13 | |

| FL-35mm | 35 | 57 | 48 | 0.47 | FL-1.37 | 1.375 | 2.23 | 1.87 | 1.00 | |

| FL-36mm | 36 | 57 | 48 | 0.45 | FL-1.50 | 1.500 | 2.23 | 1.87 | 0.93 | |

| FL-40mm | 40 | 60 | 48 | 0.56 | FL-1.625 | 1.625 | 2.35 | 1.87 | 0.91 | |

| FL-45mm | 45 | 69 | 48 | 0.84 | FL-1.750 | 1.750 | 2.72 | 1.87 | 0.91 | |

| FL-50mm | 50 | 69 | 48 | 0.70 | FL-1.875 | 1.875 | 2.72 | 1.87 | 0.82 | |

| FL-55mm | 55 | 75 | 49 | 0.62 | FL-2.00 | 2.000 | 2.95 | 1.87 | 1.54 | |

| FL-56mm | 56 | 75 | 49 | 0.60 | FL-2.50 | 2.500 | 3.47 | 1.87 | 1.87 | |

| FL-3.00 | 3.000 | 3.47 | 1.87 | 1.30 | ||||||

|

|

|

| Slide locking collar as shown | Locking collar holds reel. | To release, hold body and pull release ring. This makes the "gap" between the body and ring larger allowing the FastLock to slide off easily. |