- About

- Composite Flyer Bows

- Air Wipes

- Ceramic Eyelets & Pulleys

Keir Manufacturing

KEIR Manufacturing, Inc. is a North Carolina, USA based company that manufactures and markets a large variety of technical ceramic and engineered products serving a diverse group of industries world-wide.

Started in 1983 as a producer of premium technical ceramic parts for the fiber and textile industry, KEIR Manufacturing has applied its materials know-how and advanced manufacturing techniques to serve many diverse industries world-wide. All our products reduce operating costs and improve productivity of our customers’ operations. We make better products, which allow our customers to make products better.

For the Wire and Cable industry worldwide, KEIR’s products include a wide range of high purity Ceramic Guides and the Frontiersman line of Air Wipes. In 2010 with the acquisition of the Wire Products business unit of Kamatics Aerospace, state of the art Composite Flyer Bows and Ceramic Pulleys were added for this industry.

KEIR produces engineered ceramic Guides for the Textile, Core Tips for Brick and Nozzles for Sandblasting industries as well as high-temperature Furnace Components and a large number of other Specialty Applications.

We established an abrasives division in 2001 to manufacture superior quality Sharpening, Dressing, and Polishing Stones.

Composite Flyer Bows

New Technologey- The Backbone

The more aerodynamic BackBone design functions at lower power consumption (up to 40% less energy) and higher TPM, resulting in improved wire quality and a further reduction in bow breakage.

Features

- Improved bow Strength (no holes)

- Wire is out of the Air Stream

- Bow shaped like a wing for improved aerodynamics and low CW factor

- Wear strip eliminated and replaced by wear bushings with windows for easy inspection and dust cleaning

- Wear bushings can be ceramic, steel (48 - 58 Rc) and other materials or coatings

- Wear bushings improve support or difficult to make products

- No wire pinching between guide and wear strip

Benefits

- Higher TPM - Maintaining Wire Quality

- Reduced elongation at higher TPM

- Reduced bow breakage

- Increased life on wear surfaces, reducing downtime and maintenance

- Easy assembly and change out of wear bushings

- Wire breaks are contained within the bow - extending bow life

Air Wipes

Finally, an Air Wipe that really works!

Just when you had about given up on finding Air Wipes that would dry wire completely with compressed air, KEIR has developed a dependable, simple and cost-effective new design. Boldly independent by design, reliable yet thrifty, the FRONTIERSMAN makes the most of any situation.

Reduce Air Consumption & Rugged Design

Designed to use the full potential of the compressed air source to perform the work of drying your product, the FRONTIERSMAN quietly accomplishes more with less. High density ceramic inserts in a tough polymer housing provide a long rugged life to the FRONTIERSMAN. U.S.

What is so unique to KEIR’s design

Keir FRONTIERSMAN Air Wipes are custom made to your specified wire diameter. Their Air Wipes are designed to operatre for the designated wire at a stardard 60psi/4.14 bars.

KEIR’s design relies on the controlled use of compressed air which is allowed to decompress to atmospheric pressure within a carefully sized chamber. The air accelerates to nearly the speed of sound in a thin layer surrounding the wire. This release of kinetic energy stored when the air was compressed does far more work than other systems that rely on high volumes of air. The wire path is lined with high-density ceramic material for long life. The configuration of the ceramic keeps the wire centered within the airflow

Ceramic Pulleys/Shcaves with Aluminium and Plastic Flanges

• Dynamically Balanced to 2500 RPM• 95% Alumina• Replaceable Wear Resistant Ceramic Rings• Press Fit Bearings |

|

|

Ceramic Eyelets/Guides/Bushings

Aluminum Oxide (Alumina) Natural Sapphire hard. Homogeneous, chemically inert, mechanically strong. 99.8% pure and ultrafine particle size contribute to excellent surface finishes and dimensional accuracy. Our unique material is the ultimate for long life in guides. Color: Off-White. When ordering, specify part number followed by WAL.

- 99.8% High Purity Long Wear Materials

- Prototype Parts

- High Volume Runs

- No or Minimal Tooling Costs

- Proprietary Forming and Machining Methods

- Tight Tolerances

- Shorter Lead Times

Standard Tolerances: All dimensions +/- .010″ or 1 1/2 % whichever is greater. Tighter tolerances available on request

Use the link image below to send us you specifications:

The SureShot. (150 Series) Used on bare wire with line speeds up to 7,500 feet per minute, the SureShot is a versatile solution to wet wire problems. Sizes for wire up to .400″ O.D. fit with two standard mounting configurations. Typically offered with a 2″ x 2” x 1.5″ mounting block, SureShot inserts can be manifold mounted or inserted in clamped blocks for multi-wire lines with centers as close as one inch or 25 mm

The SureShot. (150 Series) Used on bare wire with line speeds up to 7,500 feet per minute, the SureShot is a versatile solution to wet wire problems. Sizes for wire up to .400″ O.D. fit with two standard mounting configurations. Typically offered with a 2″ x 2” x 1.5″ mounting block, SureShot inserts can be manifold mounted or inserted in clamped blocks for multi-wire lines with centers as close as one inch or 25 mm The SplitShot. (Five Series: 250, 350, 450, 500, 550) KEIR’s clamshell style SplitShot Air Wipe is a highly effective, rugged powerhouse in a small package. Ceramic inserts line the wire path and keep the wire centered within a powerful air stream. A tough polymer housing incorporates an integral hinge that can take abuse yet comes apart easily for service. All standard fasteners, springs and hinge pins are stainless steel. The SplitShot has been used on extrusion lines as fast as 7,000 feet per minute. Each unit is sold with its own air filter regulator including gauge and drain so that proper settings are easily monitored. The standard housing for wire up to .460″ O.D. is only 2.375″ wide x 2″ tall x 3.5″ long. SplitShots can be sized for round or flat profiles up to 4.5″ O.D. or width

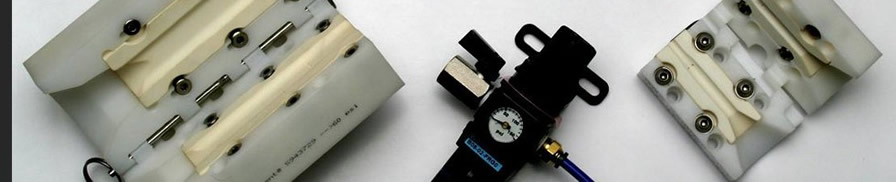

The SplitShot. (Five Series: 250, 350, 450, 500, 550) KEIR’s clamshell style SplitShot Air Wipe is a highly effective, rugged powerhouse in a small package. Ceramic inserts line the wire path and keep the wire centered within a powerful air stream. A tough polymer housing incorporates an integral hinge that can take abuse yet comes apart easily for service. All standard fasteners, springs and hinge pins are stainless steel. The SplitShot has been used on extrusion lines as fast as 7,000 feet per minute. Each unit is sold with its own air filter regulator including gauge and drain so that proper settings are easily monitored. The standard housing for wire up to .460″ O.D. is only 2.375″ wide x 2″ tall x 3.5″ long. SplitShots can be sized for round or flat profiles up to 4.5″ O.D. or width