- Products

- KAron®

- Fixed Wing Aircraft

- Rotorcraft

- Marine

- Hydropower

- Oil & Gas

- Motorsport

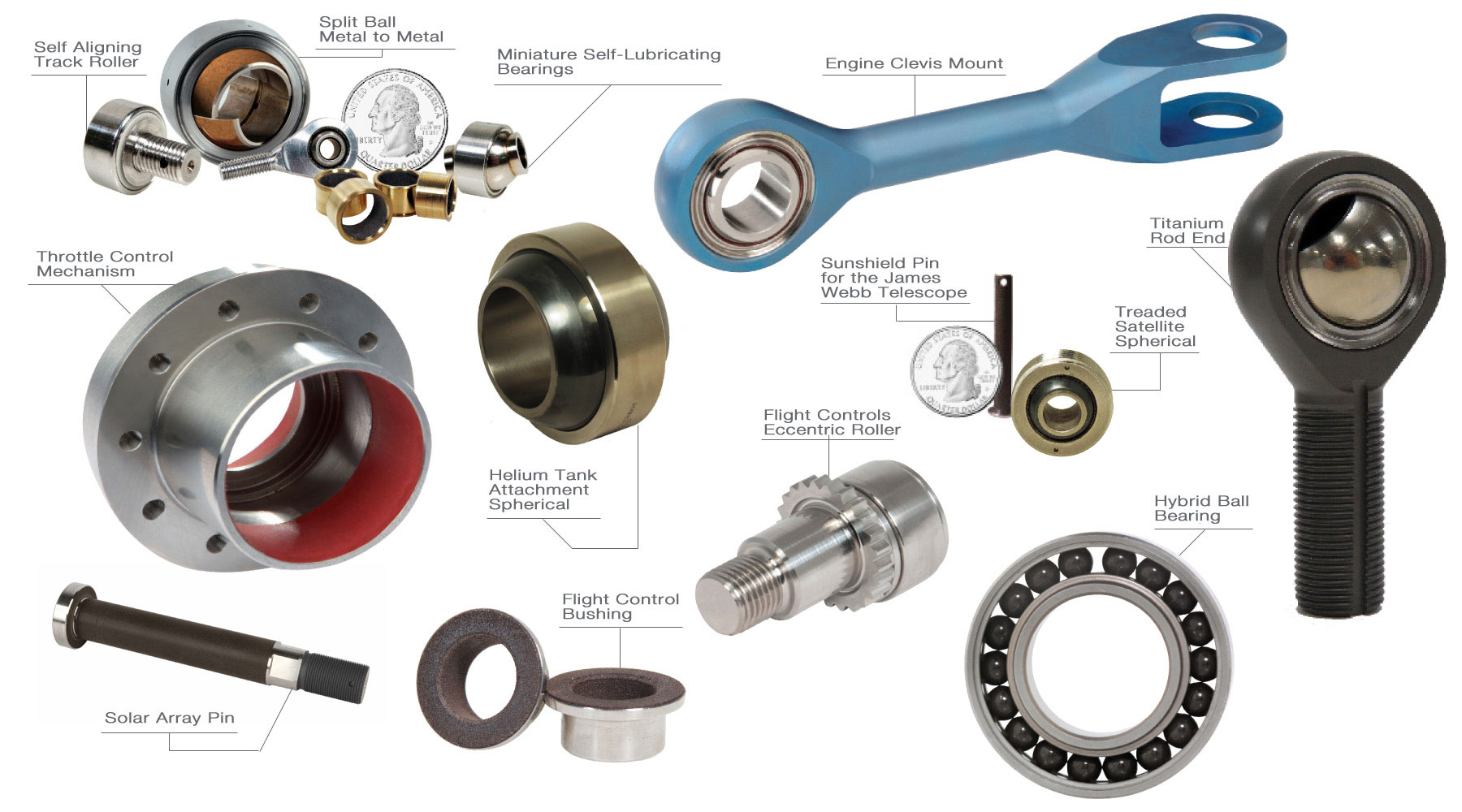

- Space

Self Lubricating Bearings

Machinable & Moldable Liner

Kamatics’ self-lubricating liner systems, including KAron®, has become an ideal replacement for PTFE fabric-lined bearings. Their liner systems performance has established superior results in providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid/debris contamination, and elevated temperatures. Their bearings can be found in thousands of high performance applications.

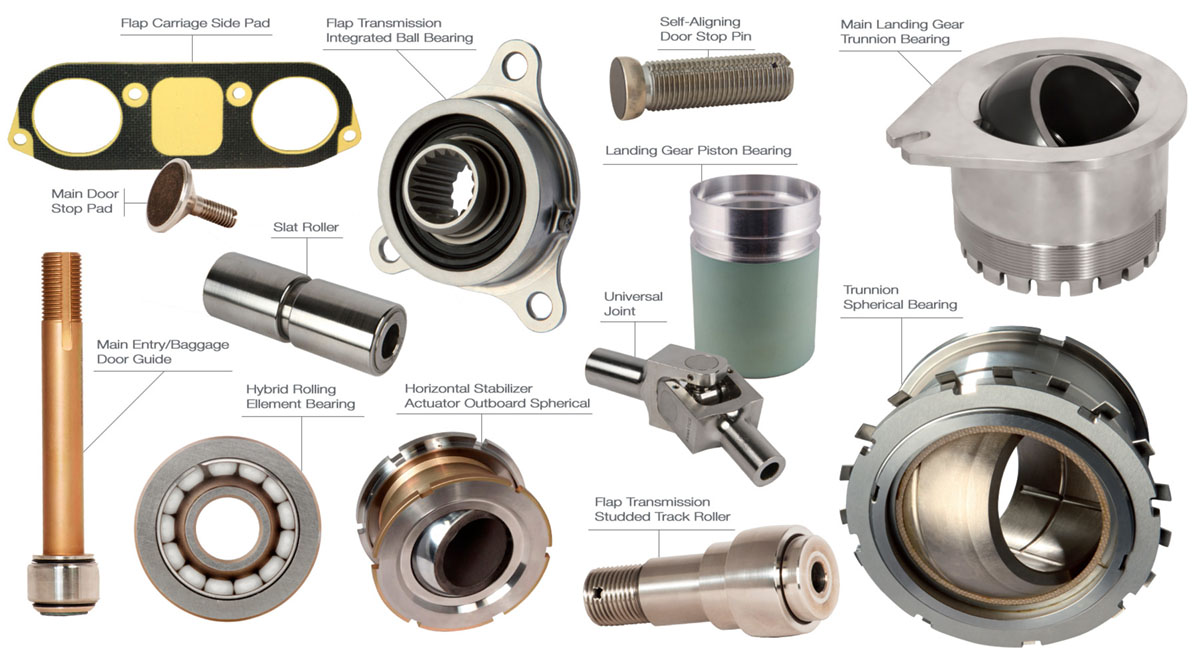

Commercial/Military Fixed Wing Aircraft

- Landing Gear

- Flight Control Systems

- Doors

- Engines

- Slats

- Vertical & Horizontal Stabilizer Bearings

Commercial/Military Rotorcraft

- Flight Control Systems

- Rotor Control Systems

- Damper Bearings

- Landing Gear

- Swash Plate Bearings

- Pitch Control Bearings

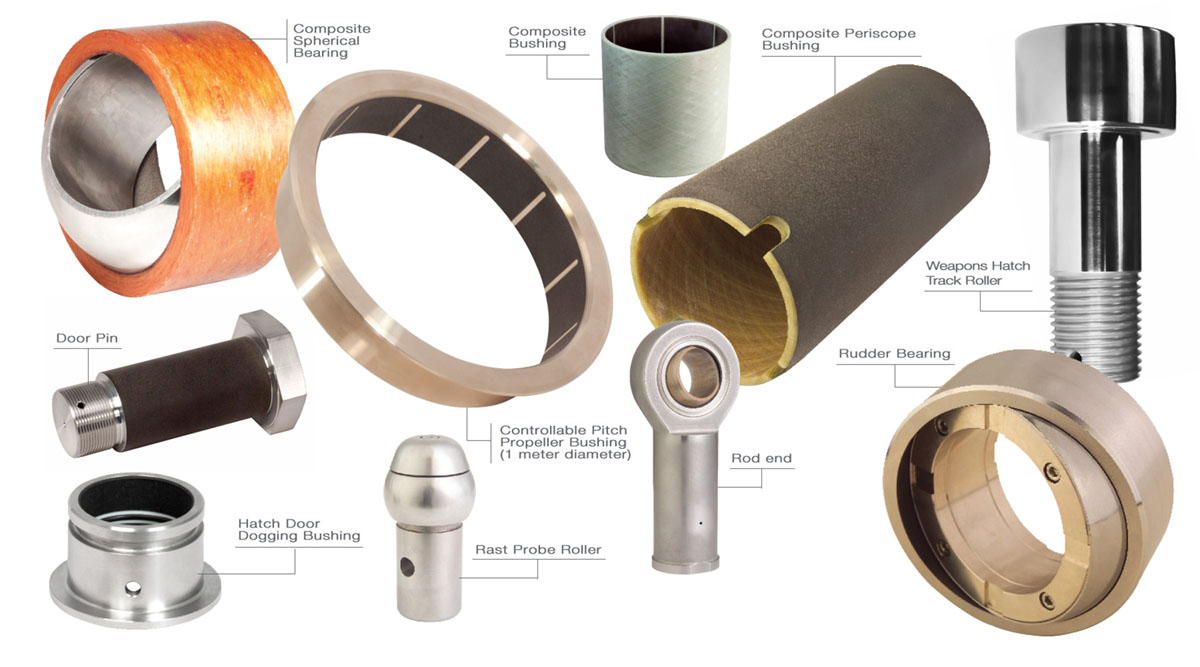

Space Vehicles & Satellites

- Flight Control Systems

- Power Systems

- Doors

- Hatches

- Solar Array Deployment Systems

Fabric Liner RWG

The RWG FRASLIP line of self-lubricating bearings are based on specially engineered liner fabrics that include PTFE and other fibers for high load, low friction applications and dramatically extend service life.

Three basic fabric formulations cover most applications however RWG have other liners for more specific or demanding applications.

Self-Lubricating Liner System FRASLIP F

- Tight woven fabric of multifilament synthetic fibers, coated (saturated) with a unique formula of PTFE, resin and special fillers

- Outstanding compatibility with bare titanium

- Non swelling

- Low outgassing, tested per mVCM ECSS Q70-02

- Qualified to SAE AS 81820, EN2755, ABS2045 plus many customer approvals

New Helicopter Liner System FRASLIP EF

- First liner system with engineered mating surface

- Tight woven fabric of multifilament synthetic fibers with interwoven

PTFE-Fibers, saturated with resin - Mating Surface super finished Tungsten Carbide

New Self Lubricating Bearing System FRASLIP T

- High temperature liner system

- Medium load rating

Downloads

- Self-Lubricating Fabric Lined Spherical Bearings

- Self-Lubricating Fabric Lined Rod End Bearings

- Self-Lubricating Fabric Lined Journal Bearings

- Fraslip A

- Fraslip EF

- Fraslip F

- Fraslip T

Rolling Element Bearings

Where lowest friction, highest accuracy and higher speeds are required, rolling element bearings are the ideal first choice. Kaman offer a wide range of designs from small deep groove ball bearings up to large, high load rating spherical roller bearings. By using special platings, steels and lubricants Kaman can cover a wide range of applications.

Features & Benefits

- Very low rotational friction

- Continuous operation possible

- Various designs:

- Deep groove ball bearings

- Angular contact ball bearings

- Self aligning ball bearings

- Spherical roller bearings

- Track roller

- Needle bearings

- Special designs

- Dry running hybrid bearings for temperatures up to 650°C

Downloads

Metal to Metal Bearings

Metal to metal bearings are traditionally used for high load applications and/or harsh conditions such as high or low temperatures. Using different types of construction and various coatings, platings and lubricants Kaman are able to ensure the best performance under almost any conditions.

Features & Benefits

- Very high load rating

- High tolerance to impact loads

- Numerous materials possible

- Cryogenic temperatures

- High temperatures up to 800°C

- Constructions:

- Formed outer ring

- Outer ring with loader slot

- Split ball design

- Vacuum compatible

Downloads

High Precision Bearings GRW

Kamatics recently acquired the GRW company whom CGB have been representing and distributing for a number of years now.

GRW produces high precision miniature ball bearings’ that perform under the most extreme conditions, temperatures (+450C to -270C), chemical exposure, salt water, blood, radiation, high speed, vacuum, vibration & more. GRW bearings are used whenever there is a need for a high precision bearing in a small confined space.

- Aerospace

- Medical & dental

- Food & beverage

- Vacuum &factory automation.

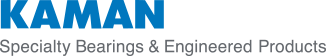

Flexible Drive Systems

Aerospace

Flight -Critical Aerospace drive system applications present some of the most challenging and demanding power transmission requirements for flexible coupling elements and Kamatics’ KAflex® and Tufflex® driveshaft have earned a well deserved reputation for safety. For close to four decades, our maintenance-free couplings have been the first choice for helicopter main-shaft and tail rotor driveline locations; applications where failure is not an option as component malfunction can mean loss of life.

Features

- No lubrication required

- Superior misalignment capability

- Integral fail-safe feature

- High torque capacity

- Rugged construction

- Damage tolerant - repairable

Benefits

- Extended service life

- Increased reliability

- Ease of inspection Cost effective

Industrial

When standard power transmission couplings fall short of performance and life requirements for critical industry applications, turn to Kamatics’ flexible drive systems for the perfect solutions. With a a unitized diaphragm-type flexible coupling design it offers an extremely capable, maintenance-free solution. The flexible drive systems are particularly well-suited for critical system applications with the potential for high angular and axial misalignments at high operating speeds.

Features

- No lubrication required

- Superior misalignment capability

- High speed capability

- High torque capacity

- Rugged construction

- High torsional stiffness

- Zero Backlash

Benefits

- High performance

- Maintenance-free

- Continuous operation, no downtime

- Increased reliability

- Longest life durability

- Cost Effective

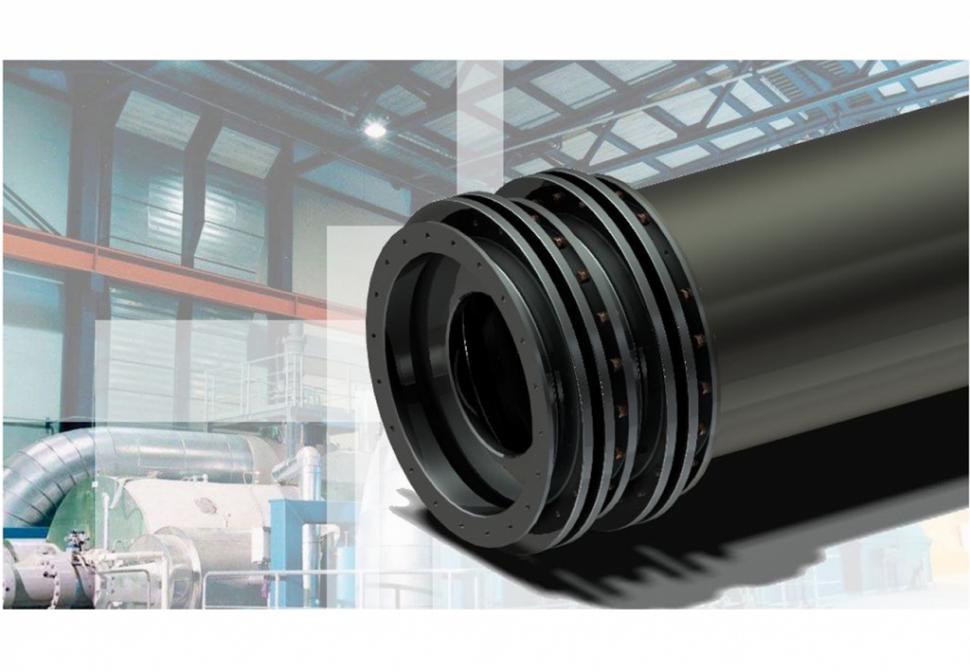

Titanium Diffusion Hardening TDH

Titanium Diffusion Hardening (TDH) is a surface-hardening process (not a coating) for titanium alloys that significantly improves its properties in lined self-lubricating bearing systems by delivering a high-hardness outer surface to the titanium material. The TDH process will consistently yield a high-hardness case layer unmatched by other titanium surface engineering processes.

Titanium Diffusion Hardening (TDH) is a surface-hardening process (not a coating) for titanium alloys that significantly improves its properties in lined self-lubricating bearing systems by delivering a high-hardness outer surface to the titanium material. The TDH process will consistently yield a high-hardness case layer unmatched by other titanium surface engineering processes.

Titanium alloy is a popular choice for bearing material for applications requiring low overall weight. However under very high bearing loads titanium alloys can exhibit less stable dynamic friction coefficients. Titanium alloy bearings can also be subject to surface distress (wear scarring of the titanium). Using a diffusion-hardened Ti64 mating surface within their self-lubricating bearing systems, KAMAN Specialty Bearings & Engineered Products has been able to alleviate wear scarring. This delivers a highly efficient, high load & lightweight bearing.

“Using our proprietary Titanium Diffusion-Hardening process, we’ve really been able to raise the bar for lightweight self-lubricating plain bearing systems. Using a diffusion-hardened Ti64 mating surface, we’ve been able to achieve KAron wear and friction results equivalent to those we experience with high-hardness stainless steels (at nearly half the assembly weight)” said Mat Mormino, VP of Engineering, KAMAN Specialty Bearings & Engineered Products.

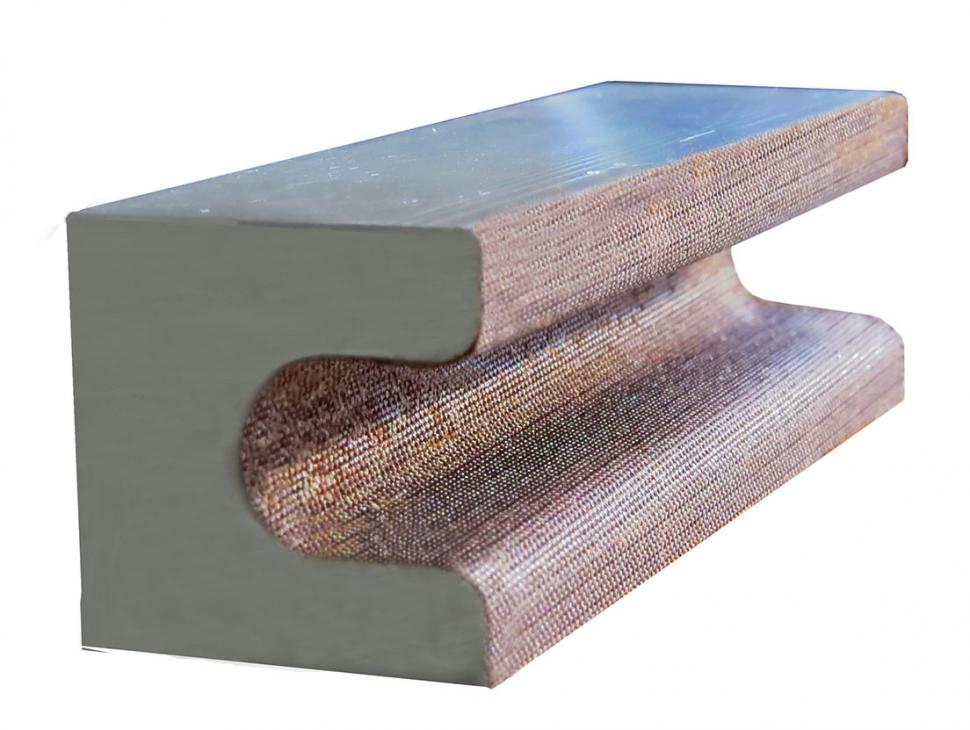

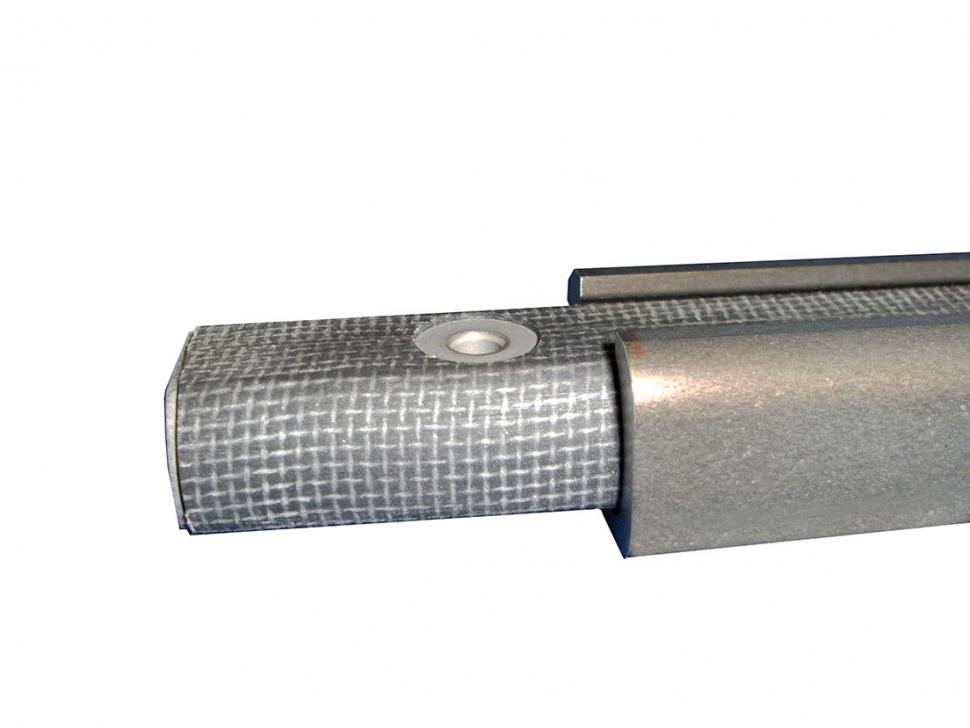

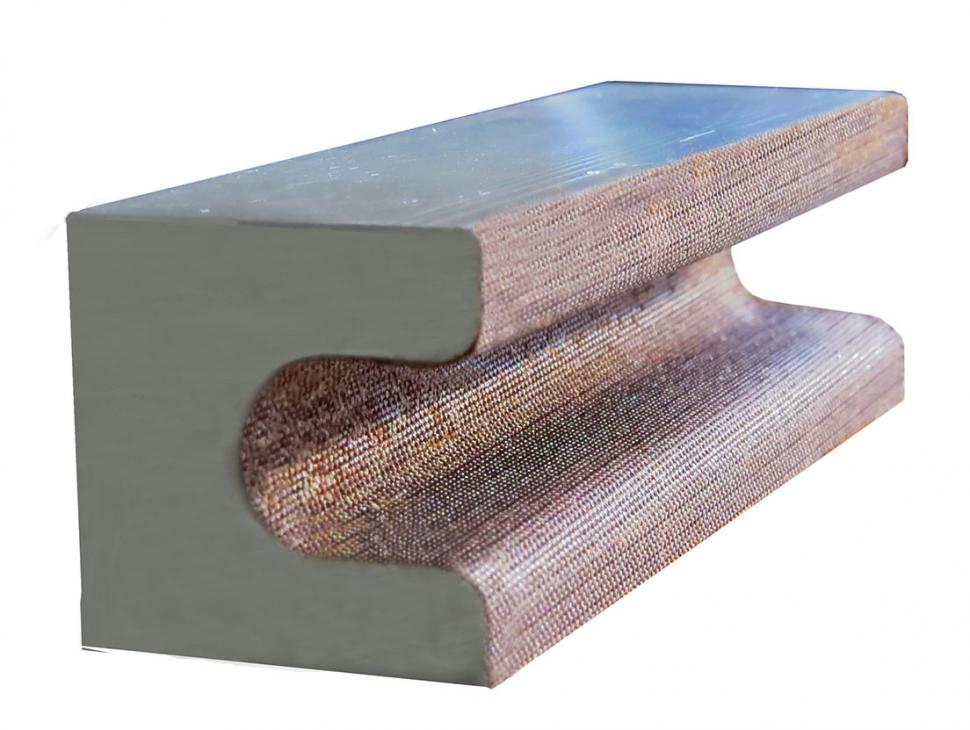

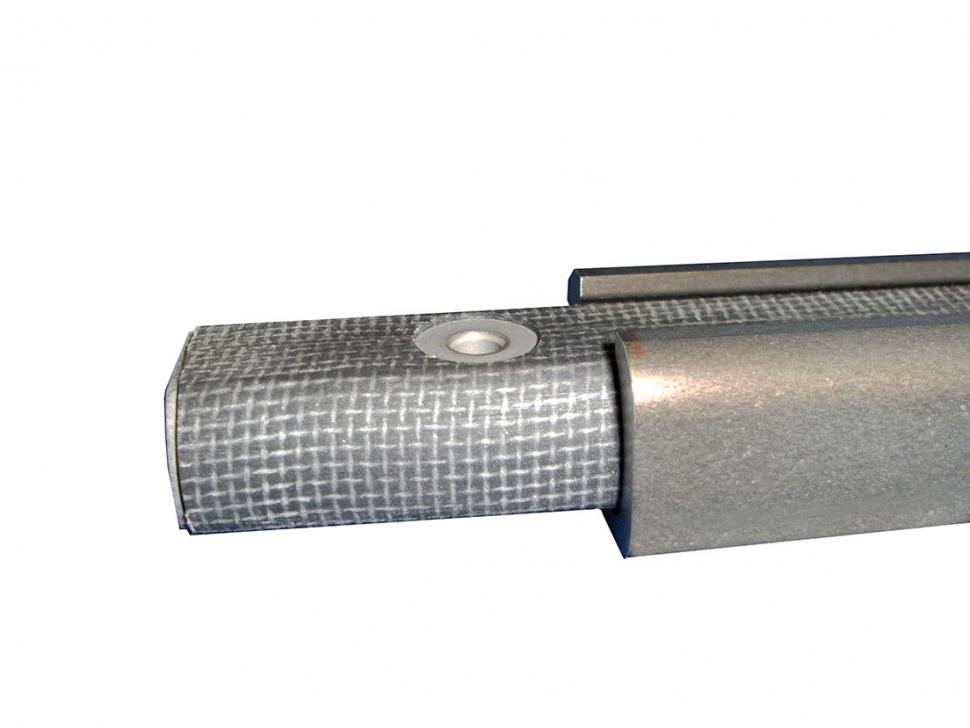

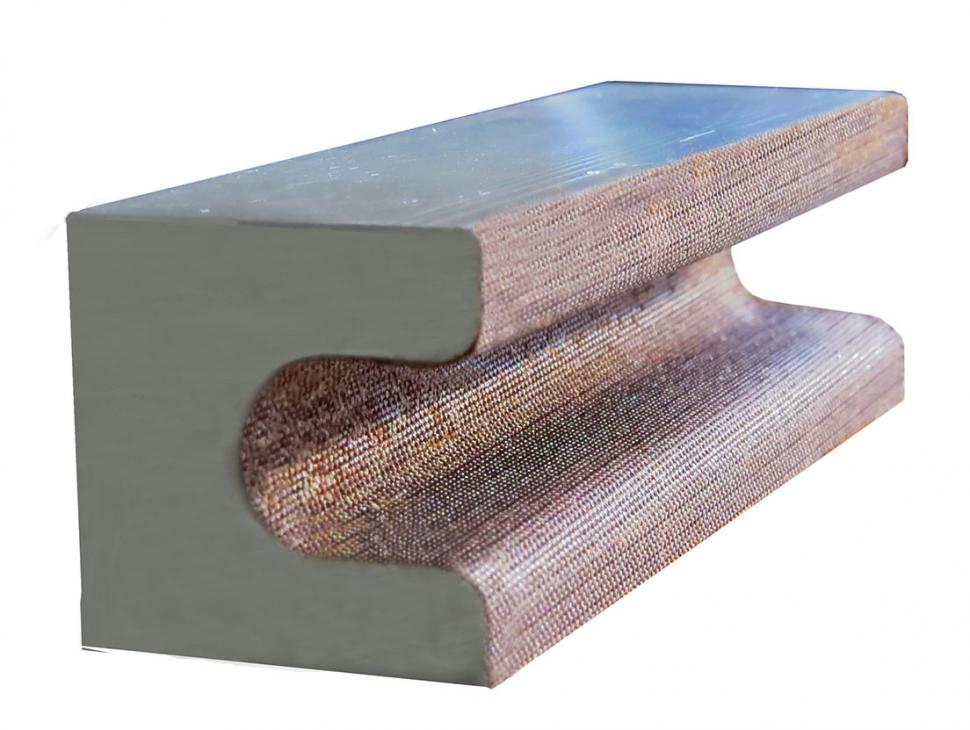

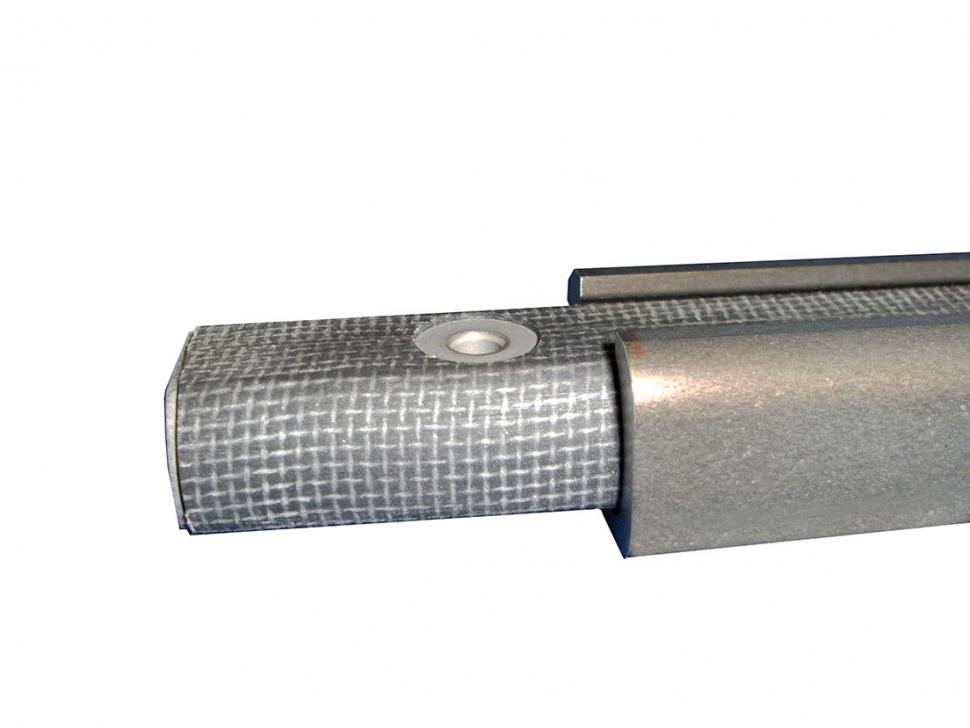

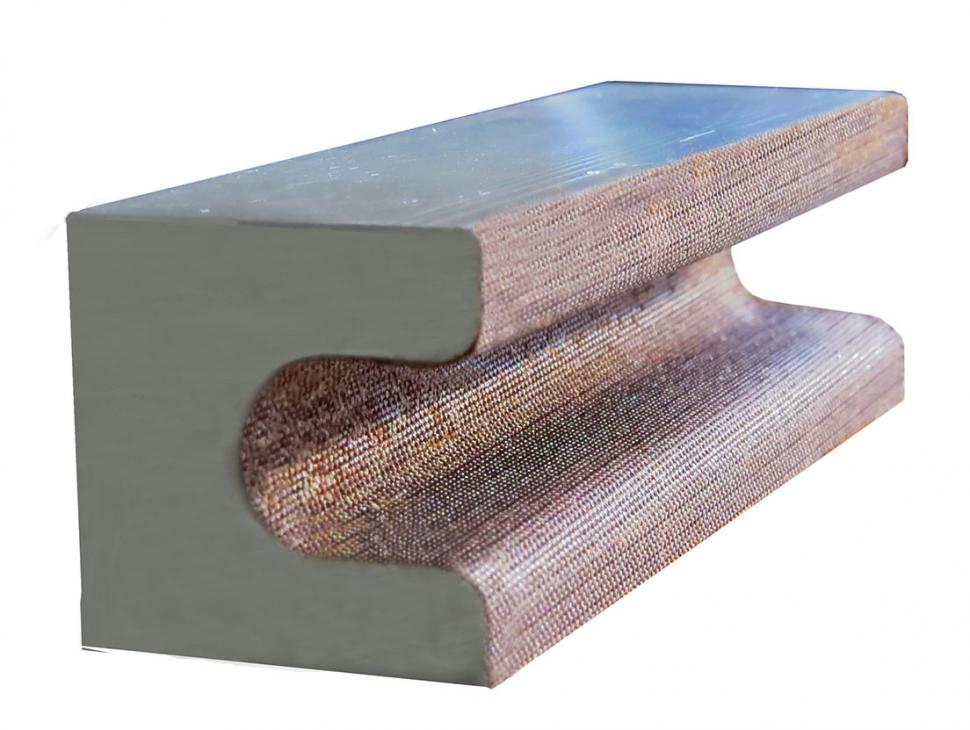

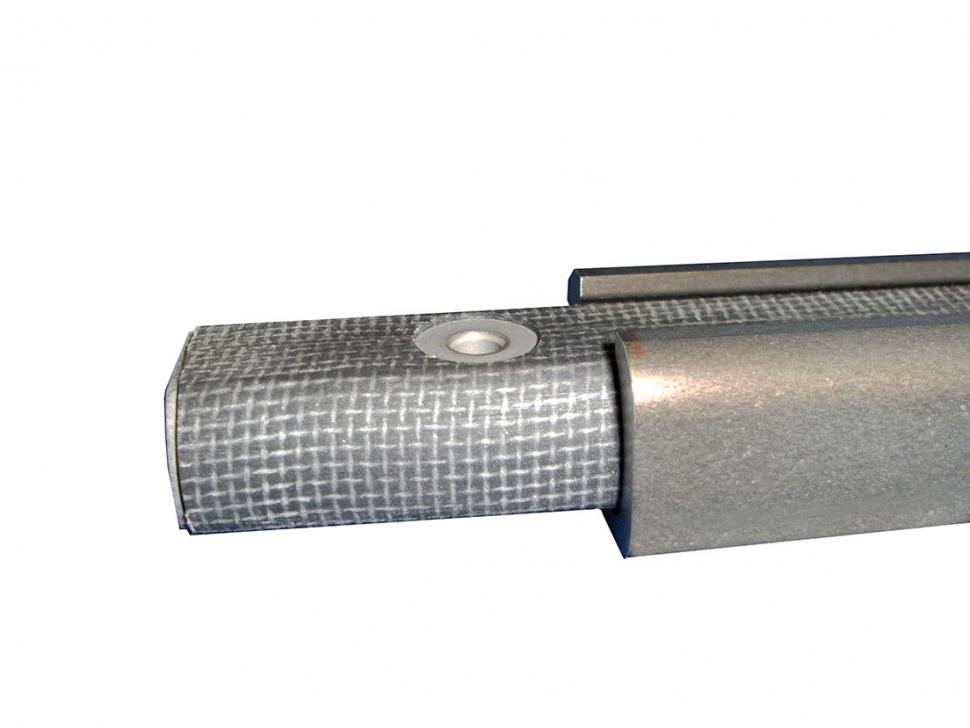

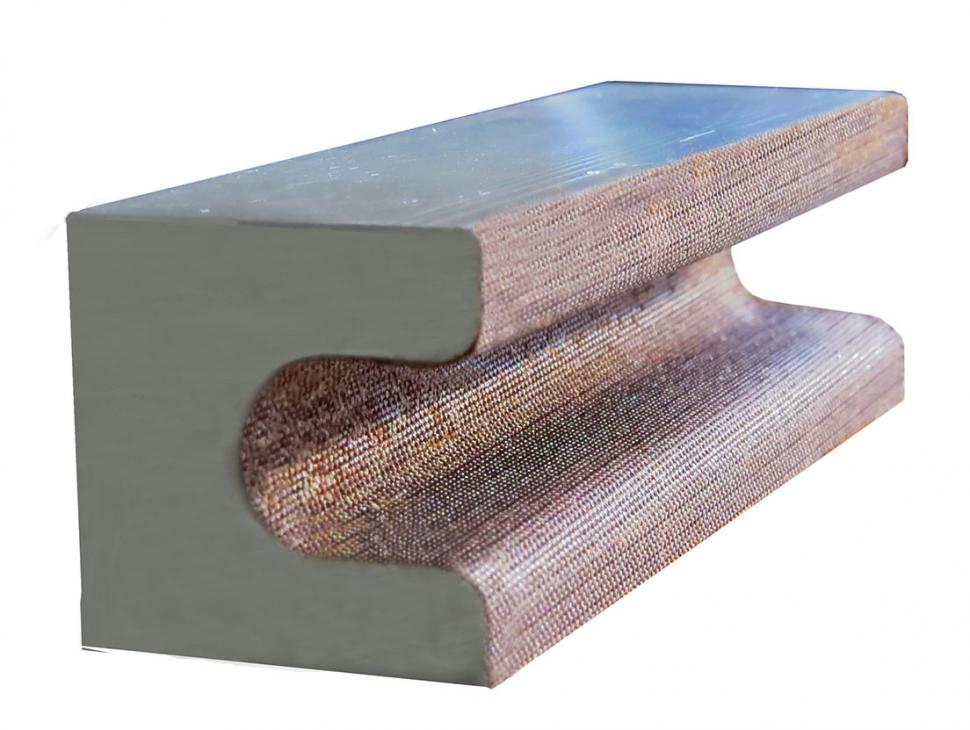

Wear Strips

Kaman offer a range of wearstrips made from their Karon liner in a range of thickness, each providing unique characteristics to prevent metal to metal to wear and fretting damage from sliding or rubbing surfaces. They are designed to be bonded onto surfaces as a protective barrier. They can be ordered as standard size sheets of as custom cut profiles.

Dry-Film Lubricant KFL-DM

Kaman`s KFL-DM is a superior alternative to dry film lube. It is a polymer based film coating impregnated with PTFE &other special fillers. KFL-DM can be applied to a large range surfaces including spline shafts and other complex geometry. KFL-DM coating is ready to go into the field as no final machining step is required and has a resulting thickness of 0.025 – 0.051mm (.001-.002”).

Benefits:

- No maintenance

- Extended life

- Superior Performance

- Cost effective

Features:

- Fretting barrier

- Fluid compatibility

- Durable

Karon Self Lubricating Bearings & Liner System

KAron is a high performance self lubricating liner system with a low wear rate.

- Track roller & cam follower bearings catalogue

- Spherical & journal bearings catalogue

- Marine bearings catalogue

- Karon wear strip more information

- KAM Tough Industrial Wear Strip more information

Features & Benefits:

- High operating loads

- Low consistent friction

- Fluid Compatibility

- Machinable

- Applied to a variety of substrates & complex geometry

- Abrasion resistant

- Long life

- 100% maintenance free

- Anti fretting properties

- 100% bond, not peelable

Liner Overview

Contact CGB for assistance on choosing the correct liner for your application.

- KAron B Data Sheet

- KAron BX Data Sheet

- KAron B Data Sheet

- KAron VS Data Sheet

- KAron T87 Data Sheet

Fixed Wing Aircraft

Kaman produce custom bearing solutions for flight controls, landing gear, doors, actuators, engines and structural attachments and can be found on many of todays aircraft. Their self lubricating bearings reduce maintenence costs, decrease weight and imporve performance and life. Their rolling ellement beairngs used unique alloys and special coatings for optimal load distribution.

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatiblity

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Rolling Element Bearings

Where lowest friction, highest accuracy and higher speeds are required, rolling element bearings are the ideal first choice. Kaman offer a wide range of designs from small deep groove ball bearings up to large, high load rating spherical roller bearings. By using special platings, steels and lubricants Kaman can cover a wide range of applications.

Features & Benefits

- Very low rotational friction

- Continuous operation possible

- Various designs:

- Deep groove ball bearings

- Angular contact ball bearings

- Self aligning ball bearings

- Spherical roller bearings

- Track roller

- Needle bearings

- Special designs

- Dry running hybrid bearings for temperatures up to 650°C

Metal to Metal Bearings

Metal to metal bearings are traditionally used for high load applications and/or harsh conditions such as high or low temperatures. Using different types of construction and various coatings, platings and lubricants Kaman are able to ensure the best performance under almost any conditions.

Features & Benefits

- Very high load rating

- High tolerance to impact loads

- Numerous materials possible

- Cryogenic temperatures

- High temperatures up to 800°C

- Constructions:

- SFormed outer ring

- Outer ring with loader slot

- Split ball design

- Vacuum compatible

Rotorcraft

Kamatics (USA) and RWG (Germany) have a long established history of designing, testing, and manufacturing the highest performing bearings and flight critical parts in the industry. They have a reputation for excelling under the most demanding conditions.

Flexible Drive Systems

Kamatics KAflex® and Tufflex® coupling systems are frequently selected and used for critical rotating applications that reqeuire a level of performance and safety that unachievable with conventional greased coupling systems & standard flex-element couplings. Kamatics Flexible Drive Systems are the perfect choice for extreme torque, excessive angular misalignment, and high operating speeds.

Features

- No lubrication required

- Superior misalignment capability

- Integral fail-safe feature

- High torque capacity

- Rugged construction

- Damage tolerant - repairable

Benefits

- Extended service life

- Increased reliability

- Ease of inspection

- Cost effective

Driveshaft Aftermarket Documentation

Aftermarket Driveshafts:

KAflex Product Support

Aftermarket Product Service Instruction Manuals:

206 A/B Series for Commercial Only

SIN 2348 Current Rev. K Dated 04-21-15

Download PDF Manual Here

206LI/LIII Series

SIN 3052 Current Rev. D Dated 03-30-15

Download PDF Manual Here

206 A/B Series Rotor Brake

SIN 2975 Current Rev. A Dated 4-18-14

Download PDF Manual Here

Aftermarket Torque Stripe Repair Kits:

Kits are available from the Henkel Corporation website. Please consult service instruction for guidelines for proper maintenance procedures before applying any torque stripe touch up. Visit the Henkel Corporation website.

Contact CGB for Overhaul & Repair

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatibility

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Rolling Element Bearings

Where lowest friction, highest accuracy and higher speeds are required, rolling element bearings are the ideal first choice. Kaman offer a wide range of designs from small deep groove ball bearings up to large, high load rating spherical roller bearings. By using special platings, steels and lubricants Kaman can cover a wide range of applications.

Features & Benefits

- Very low rotational friction

- Continuous operation possible

- Various designs:

- Deep groove ball bearings

- Angular contact ball bearings

- Self aligning ball bearings

- Spherical roller bearings

- Track roller

- Needle bearings

- Special designs

- Dry running hybrid bearings for temperatures up to 650°C

Marine

Kaman has over 40 years of experience in the marine industry and their vast knowledge of self-lubricating bearings has seen them work closely with each customer to design and implement application specific bearing solutions.

Applications:

- Navigational lock systems

- Power generation systems

- Steering and diving mechanisms

- Water tight hatches and doors and more.

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatibility

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Wear Strips

Kaman offer a range of wearstrips made from their Karon liner in a range of thickness, each providing unique characteristics to prevent metal to metal to wear and fretting damage from sliding or rubbing surfaces. They are designed to be bonded onto surfaces as a protective barrier. They can be ordered as standard size sheets of as custom cut profiles.

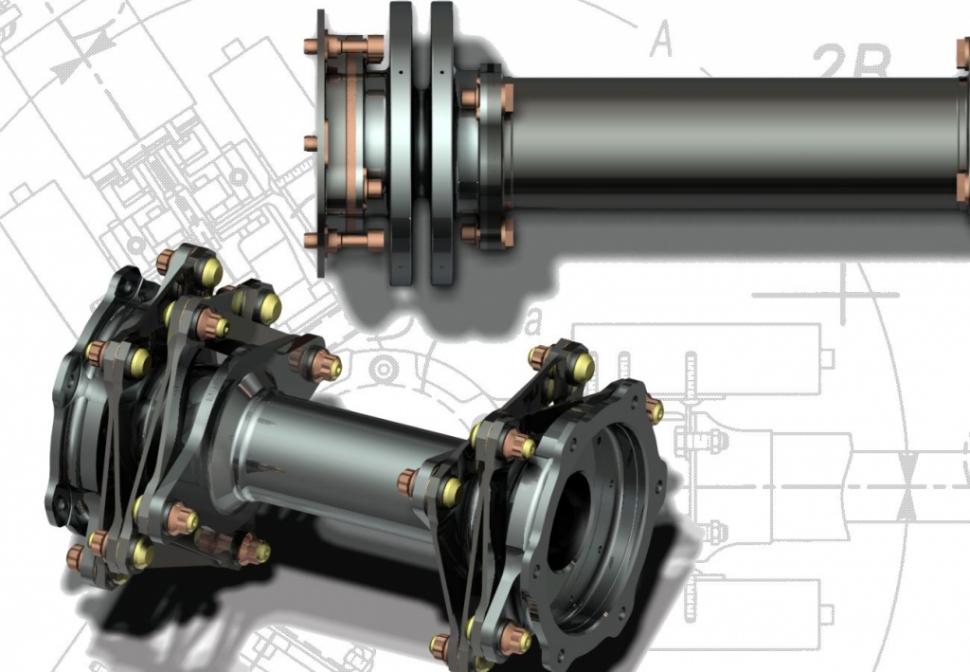

Hydropower

With Kaman Specialty Bearings and Engineering products you will be sure to reduce maintenance cost, improve performance and life in harsh environments. Kaman`s dedicated engineering staff work closely to workd with customers to design self lubricating solutions. The Karon technology delivers the highest performing, longest lasting, lowest cost to own bearings in the industry.

Applications

- Gate systems

- Kaplan hub trunnions

- Wicker gate bushings

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatibility

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Wear Strips

Kaman offer a range of wearstrips made from their Karon liner in a range of thickness, each providing unique characteristics to prevent metal to metal to wear and fretting damage from sliding or rubbing surfaces. They are designed to be bonded onto surfaces as a protective barrier. They can be ordered as standard size sheets of as custom cut profiles.

Oil & Gas

Kaman has over 20 years of experience in oil and gas, with their vast knowledge and understanding of self-lubricating bearings and a team of over 35 design engineers, they closely with each customer to design and implement application-specific bearing solutions. Our self-lubricating bearing technology is found around the globe.

Applications

- Down-hole drilling

- Oil sands shovels

- Ball valves

- Risers

- Moorings

- Cranes

- Controllable pitch blades and deck equipment.

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatibility

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Metal to Metal Bearings

Metal to metal bearings are traditionally used for high load applications and/or harsh conditions such as high or low temperatures. Using different types of construction and various coatings, platings and lubricants Kaman are able to ensure the best performance under almost any conditions.

Features & Benefits

- Very high load rating

- High tolerance to impact loads

- Numerous materials possible

- Cryogenic temperatures

- High temperatures up to 800°C

- Constructions:

- Formed outer ring

- Outer ring with loader slot

- Split ball design

- Vacuum compatible

Rolling Element Bearings

Where lowest friction, highest accuracy and higher speeds are required, rolling element bearings are the ideal first choice. Kaman offer a wide range of designs from small deep groove ball bearings up to large, high load rating spherical roller bearings. By using special platings, steels and lubricants Kaman can cover a wide range of applications.

Features & Benefits

- Very low rotational friction

- Continuous operation possible

- Various designs:

- Deep groove ball bearings

- Angular contact ball bearings

- Self aligning ball bearings

- Spherical roller bearings

- Track roller

- Needle bearings

- Special designs

- Dry running hybrid bearings for temperatures up to 650°C

Wear Strips

Kaman offer a range of wearstrips made from their Karon liner in a range of thickness, each providing unique characteristics to prevent metal to metal to wear and fretting damage from sliding or rubbing surfaces. They are designed to be bonded onto surfaces as a protective barrier. They can be ordered as standard size sheets of as custom cut profiles.

Motorsports

For over 40 years the Kaman engineers have solved the most demanding bearing and driveline application challenges. KamaticsRWG self-lubricating & rolling element technology increases performance by offering low friction, high load and high stiffness solutions. Our solutions can be found in Formula One, Indy, and Rally Cars around the globe.

Applications

- Steering

- Suspensions including wishbones

- Push rods & stabilizer bars.

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatibility

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Metal to Metal Bearings

Metal to metal bearings are traditionally used for high load applications and/or harsh conditions such as high or low temperatures. Using different types of construction and various coatings, platings and lubricants Kaman are able to ensure the best performance under almost any conditions.

Features & Benefits

- Very high load rating

- High tolerance to impact loads

- Numerous materials possible

- Cryogenic temperatures

- High temperatures up to 800°C

- Constructions:

- Formed outer ring

- Outer ring with loader slot

- Split ball design

- Vacuum compatible

Wear Strips

Kaman offer a range of wearstrips made from their Karon liner in a range of thickness, each providing unique characteristics to prevent metal to metal to wear and fretting damage from sliding or rubbing surfaces. They are designed to be bonded onto surfaces as a protective barrier. They can be ordered as standard size sheets of as custom cut profiles.

Space

Kaman specialty bearings delivers performance, reliability and extended life for demanding space applications.

- Solar array pins

- Arm linkages

- Flight controls

- Helium tank attachments

- Sunshields

- Engine mounts and more

Self Lubricating Bearings

With its high performance and low wear rate, Kaman`s self-lubricating liner systems have superior results, providing longer life and lower maintenance costs, even when operating in areas of high moisture, fluid & debris contamination, and high temperatures.

Features & Benefits

- High Operating Load

- Low Consistent Friction

- Fluid Compatibility

- Can Be Machined

- Applied to a Variety of Substrates

- Abrasion Resistance

- Long Life

- 100% Maintenance Free

- 100% Bond, Non-Peelable

- Applied to Complex Geometry

- Wide Liner Thickness Range

- Anti-Fretting Properties

Metal to Metal Bearings

Metal to metal bearings are traditionally used for high load applications and/or harsh conditions such as high or low temperatures. Using different types of construction and various coatings, platings and lubricants Kaman are able to ensure the best performance under almost any conditions.

Features & Benefits

- Very high load rating

- High tolerance to impact loads

- Numerous materials possible

- Cryogenic temperatures

- High temperatures up to 800°C

- Constructions:

- Formed outer ring

- Outer ring with loader slot

- Split ball design

- Vacuum compatible

Titanium Diffusion Hardening (TDH)

Titanium Diffusion Hardening (TDH) is a surface-hardening process (not a coating) for titanium alloys that significantly improves its properties in lined self-lubricating bearing systems by delivering a high-hardness outer surface to the titanium material. The TDH process will consistently yield a high-hardness case layer unmatched by other titanium surface engineering processes.

Titanium Diffusion Hardening (TDH) is a surface-hardening process (not a coating) for titanium alloys that significantly improves its properties in lined self-lubricating bearing systems by delivering a high-hardness outer surface to the titanium material. The TDH process will consistently yield a high-hardness case layer unmatched by other titanium surface engineering processes.

Titanium alloy is a popular choice for bearing material for applications requiring low overall weight. However under very high bearing loads titanium alloys can exhibit less stable dynamic friction coefficients. Titanium alloy bearings can also be subject to surface distress (wear scarring of the titanium). Using a diffusion-hardened Ti64 mating surface within their self-lubricating bearing systems, KAMAN Specialty Bearings & Engineered Products has been able to alleviate wear scarring. This delivers a highly efficient, high load & lightweight bearing.